Aachen researchers develop sustainable artificial turf

The current European Football Championships 2024 in Germany will be played on natural turf, which is very costly to maintain, does not tolerate high frequency of use and has a limited service life of only 6 months in some cases. Artificial turf is easier to maintain and correspondingly popular. In Germany, there are estimated to be more than 5,000 artificial turf pitches and as many as 25,500 across the EU. The drawback: the enormous annual emission of microplastics in the form of infill material, the high CO2 impact and the not environmentally friendly disposal. Researchers in Aachen presented a sustainable alternative: BioTurf is a new artificial turf system made from bio-based polymers that no longer requires polymer infill material!

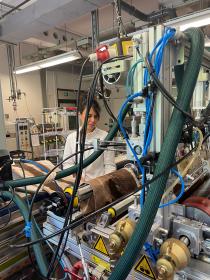

"Every year, around 500 kilograms of plastic granules are produced per artificial turf pitch, which have to be refilled as infill. This also corresponds to the amount that potentially enters the environment as microplastics per sports pitch," explains Dr Claudia Post from TFI. With an estimated 25,000 artificial turf pitches in the EU, artificial turf in Europe alone produces 12,750 tonnes of microplastics that end up in the environment every year! The TFI - Institut für Bodensysteme an der RWTH Aachen e.V., Institute for Research, Testing and Certification in Europe for Indoor Building Products, has developed the innovative artificial turf system together with the ITA (Institute for Textile Technology at RWTH Aachen University) and in collaboration with the company Morton Extrusionstechnik (MET), a specialist in artificial turf fibres.

"New artificial turf pitches will be phased out by 2031 at the latest due to the ban on plastic granules. Even now, artificial turf pitches with infill material are no longer being subsidised," says Dr Claudia Post. For grassroots sports, clubs, cities and local authorities, converting their existing artificial turf pitches will be a mammoth task in the coming years, as artificial turf pitches have to be replaced every 10-15 years. With BioTurf, an environmentally friendly alternative is now available! The surface can be played on like any other, whether running, passing or kicking. Short, heavily crimped blades support longer blades and this simple approach increases playing comfort. BioTurf fulfils all quality requirements and standards for the highest footballing demands.

"BioTurf is an innovative, holistic solution," emphasises Dirk Hanuschik from TFI. "We use rapeseed oil and agricultural waste that does not compete with food production. BioTurf is also almost completely recyclable".

This is in stark contrast to conventional artificial turf, which can currently only be thermally utilised, i.e. burned to generate heat.

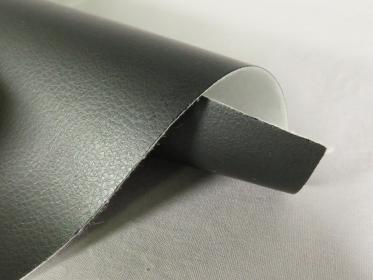

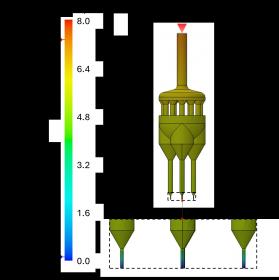

As BioTurf does not require the traditional latex process at all, the energy-intensive drying process can be dispensed with, which has a positive effect on the price. Latex is also difficult to recycle. In contrast, BioTurf uses the new thermobonding technology. Here, the thermoplastic pile yarns are thermally fused to the backing. Further development steps still need to be taken in the endeavour to develop a 100% mono-material artificial turf, as a few percent polypropylene still needs to be processed in the backing in addition to the polyethylene fibre material in order to protect it during thermobonding. However, this does not hinder its recyclability.

TFI - Institut für Bodensysteme an der RWTH Aachen e.V.