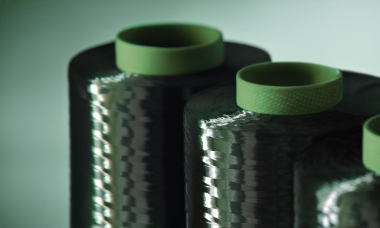

KARL MAYER: New composite machine MAX GLASS ECO

KARL MAYER Technische Textilien launches the new MAX GLASS ECO, a composite machine with a focus on standard non-crimp fabrics made of glass fibers.

The MAX GLASS ECO incorporates proven solutions from the KARL MAYER GROUP's range of multiaxial machines, including features from its predecessor, the MAXTRONIC®, and combines these with sophisticated new technical developments. The result is a production machine for the economical manufacture of standard glass fiber articles, especially non-crimp fabrics for the wind power industry.

The multiaxial warp knitting machine is extremely efficient, affordable and, unlike the previous MAXTRONIC®, sufficiently flexible thanks to various optional functions. At a rotational speed of up to 1,800 min-1, a maximum output of 410 m/h is achieved.

The MAX GLASS ECO is available with a working width of 101″ and is suitable for laying angles of +/-45°. A complementary layering system ensures a uniform take-up speed and therefore gentle processing of the fiber material. This sophisticated weft tension compensation device is one of a whole series of tried and tested features of KARL MAYER multiaxial technology that have been integrated into the new machine. Other adopted solutions include the Fiber Chopping Unit, which allows glass fiber chips to be introduced into the laying process and thus cover more fields of application, and a single pin transport chain for a processing method with less waste.

Newly developed innovations also ensure even better performance, including the fixed layer system, which ensures high placement precision at all laying angles. Other equipment details with added value for the customer include a conveyor belt across the full working width, the walking needle system, which prevents the formation of lanes even with long stitch lengths, and the fitting of single compound needles, which can be changed efficiently.

KARL MAYER Verwaltungsgesellschaft AG