Archroma and Jeanologia launch ‘Pad-Ox G2 Cold’, a water-saving dyeing process

Archroma, a global leader in specialty chemicals towards sustainable solutions, and Jeanologia, a world leader in sustainable and efficient technology development, today announced the launch of ‘Pad-Ox G2 Cold’, a water-saving dyeing process at room temperature for casual looks.

Archroma initially introduced its eco-advanced Pad-Ox dyeing process for woven fabrics, and then used it as part of its ADVANCED DENIM concept. By combining the oxidation and fixation steps, it is possible to shorten the dyeing process and thus realize substantial resource savings in water, wastewater, cotton waste, and energy.

Over the years the company has worked with its textile manufacturers and partners to improve the Pad-Ox process, in particular woven applications such as chinos and casual wear. To achieve maximum positive impact, Archroma is using its Diresul® range of low sulfide sulfur dyes and, more recently, its innovative plant-based range of EarthColors®. A wide selection of dyes from these two ranges have received the Cradle-to-Cradle Product Innovation Institute’s Platinum Level Material Health Certification.

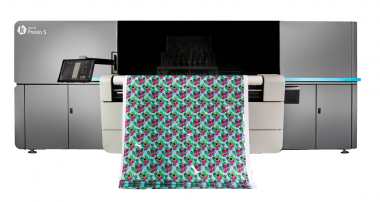

Meanwhile, Jeanologia has been working on the technology side, with laser and eco-finishing solutions for more than 25 years, accompanying the textile industry on their way to producing with zero discharge. In 2008, the company introduced its G2 Dynamic the first ozone treatment for continuous fabric that dramatically reduces the amount of water and chemicals used, while at the same time saving costs at the mill and eventually at the garment finishing facilities. This technology makes fabric more stable and consistent and prepares the fabric better for the use of other technologies like laser. This machinery can be used along with Pad-Ox technology to help cleaning fabric thus improve fastness results. While it allows process to work at room temperature.

Project focus on water saving

Archroma and Jeanologia therefore understandably decided to team up and combine their expertise in sustainable dyeing and finishing technologies. The objective of the project was to improve the Pad-Ox dyeing process even further, in particular in one area that still offered room for positive impact: temperature and fastnesses.

The new ‘Pad-Ox G2 Cold’ dyeing process works thanks to the insertion of very small machinery into the existing finishing range process, using cold processing and thus operating with much less water, carbon footprint and energy than traditional benchmark fabric finishing processes, whilst retaining the water and other resource savings offered by the Pad-Ox technology.

Maximum savings can be achieved by mills and garment manufacturers who wish to switch from a conventional dyeing process straight to ‘Pad -Ox G2 Cold’ to obtain high quality fabrics for comfortable and casual wear.

EMG