AZL is building on the success of the study on Composites in Buildings & Infrastructure

The AZL will continue its collaboration on composites in buildings and infrastructure after completing an initial market and technology study which identified new potentials for composite technologies in buildings and infrastructure markets. The aim of the new AZL Workgroup which will meet for the first time on January 25th, 2018 is to jointly develop new applications and to support the business development for composites in these two growing markets. The meeting is open to interested companies from the composite industry as well as the building and infrastructure markets.

The aim of the initial workgroup meeting will be to turn insights from the study into a long-term workgroup collaboration and to define topics and initiatives for the joint cooperation in the field of process and manufacturing technologies, fire safety regulations, materials as well as standards and norms. Industrial keynote presentations will introduce these action fields and will provide an insight into building and infrastructure applications for composites. The meeting will furthermore provide a platform to network with companies along the entire composite value chain.

Dr. Amer Affan, CEO and founder of AFFAN Innovative Structures based in Dubai is in charge of various composite projects for buildings such as the Museum of the Future in Dubai: “We have been utilizing structural composites in construction since 2010. Composites is a truly high-tech material compared with the traditional building materials (steel, concrete, timber and aluminum) but it is still to be recognized as such in the conservative and price-sensitive building industry. AZL, particularly its location at the RWTH Aachen University and its partner companies, offers a good platform to progress the use of composites in construction.”

AZL together with more than 25 companies just completed the Joint Market and Technology Study on “New Potentials for Composite Technologies in Buildings and Infrastructure” establishing a broad knowledge on business opportunities for composite technologies in these two growing markets. In a structured approach, the study determined the key segments as well as the technologies/applications with the highest market and technological potential. Analyses of 20 market segments, investigation of 438 applications, technology analyses of 25 highlight components and 11 detailed business cases were elaborated throughout the study. Additional to requirement analyses for materials and production technologies, new concepts for efficient profitable production technologies and cost engineering analysis were developed. With the workgroup, the AZL will take this initiative a step further with the aim to build a long-term cooperation platform for composites in buildings and infrastructure markets.

Justin Jin, CEO of the Korean company AXIA Materials participated in the study and is part of the AZL Partner Network: “As producer of large thermoplastic composite sheets and composite SIP (Structural Insulated Panel), we are eager to drive composites in B&I applications with the best efficient way. The AZL study on Buildings and Infrastructure provided us a great networking with key players in this business field and opportunities to strengthen our products with the key elements from partners. The study also gave us a proper market understanding including market size/volume in numbers to prove the value of this technology to building industry. We are looking forward to following up on these first insights and to realize applications with the AZL and its partners.”

Besides the networking options, the meeting will offer the opportunity to get an insight into the activities of the AZL Network consisting of nine research institutes at the RWTH Aachen Campus and more than 80 companies from 21 countries. During an optional guided tour, participants will visit selected institutes at the RWTH Aachen Campus. The meeting is open to all interested companies and free of charge.

More Information on Meeting and the Study

Information on AZL activities in the field of buildings and infrastructure:

www.azl-lightweight-production.com/composites-buildings-infrastructure

Details and registration to first Workgroup Meeting on January 25th, 2018:

http://www.azl-lightweight-production.com/termine/1st-workgroup-meeting-buildings-infrastructure

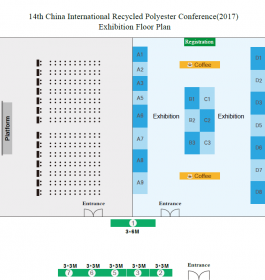

Picture 1: The AZL Joint Market and Technology Study on “New Potentials for Composite Technologies in Buildings and Infrastructure Markets” followed a structured approach to identify 438 potential applications from 20 market segments. 25 of these were analyzed in technology analyses and 11of these in detailed business cases.

Picture 1: The AZL Joint Market and Technology Study on “New Potentials for Composite Technologies in Buildings and Infrastructure Markets” followed a structured approach to identify 438 potential applications from 20 market segments. 25 of these were analyzed in technology analyses and 11of these in detailed business cases.

Picture 2: Affan Innovative Structures is making the façade of the Museum of the Future which is currently under construction in Dubai. The façade will be made of fiber-reinforced stainless steel. Copyright: Affan Innovative Structures.

Picture 2: Affan Innovative Structures is making the façade of the Museum of the Future which is currently under construction in Dubai. The façade will be made of fiber-reinforced stainless steel. Copyright: Affan Innovative Structures.

Picture 4: 25 companies participated in the AZL study on “New Potentials for Composite Technologies in Buildings and Infrastructure Markets” which started in 2016 and was completed in September 2017. Copyright: AZL Aachen GmbH/Keller.

Picture 4: 25 companies participated in the AZL study on “New Potentials for Composite Technologies in Buildings and Infrastructure Markets” which started in 2016 and was completed in September 2017. Copyright: AZL Aachen GmbH/Keller.

AZL Aachen GmbH in cooperation with Aachen Center for integrative Lightweight Production (AZL) of RWTH Aachen