ITM at JEC 2023

From April 25th to 27th, 2023, the Institute of Textile Machinery and High Performance Material Technology (ITM) of TU Dresden will be exhibiting at the pavilion SAXONY! at JEC World 2023.

The ITM will provide a comprehensive overview of its current research in the field of machine and product development along the entire textile process chain.

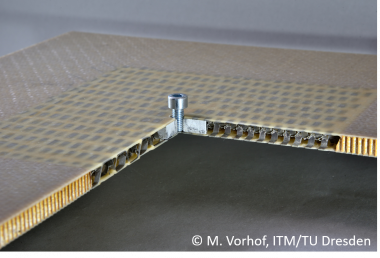

The upcoming JEC 2023 exhibition will highlight innovative Customised Connective Cores (CCC), which are custom-made core-insert structures additively manufactured using cellular metal and a form-fit integrated insert. These CCCs can be seamless integrated either as patches or as full-surface core material into lightweight panels, offering significantly improved load-bearing behavior (especially 4 times the load-bearing capacity and fail-safe behavior) compared to existing technologies. This breakthrough opens up new possibilities for fastening lightweight panels.

Another highlight at the exhibition is the repair process for fibre-reinforced composites (FRP) developed at the ITM. Instead of mechanically grinding the damaged area, the matrix in the repair area is locally dissolved using a UV-rays-induced depolymerisation process. Damaged fibres can thus be replaced by a customized repair patch. Free yarn ends on the textile repair patches are spliced with the UV-exposed yarn ends in the repair area using an adapted splicing process. In this way, a very clean, simplified and mechanically improved repair area can be achieved compared to the state of the art.

The diverse possibilities offered by the structure and process simulation of textile high-performance materials and textile manufacturing processes will also be presented. By means of multi-scale modelling and simulation, a profound understanding of materials and processes is achieved at the ITM. Finite element models on the micro, meso and macro scale have been developed and validated for this purpose. Examples from current ITM research projects demonstrate the various possibilities and areas of application of modern simulation methods in the field of textile technology.

Moreover, an innovative process for the integral manufacturing of 3D rib-stiffened preforms with complexly arranged stiffeners in 0°, 90° and ± 45° orientation was developed and successfully implemented at the ITM. Due to the process-integrated structure fixation and the continuous fibre reinforcement between shell and rib structure, the 3D preforms are perfectly suited for the production of highly load-bearing FRP components with increased bending stiffness, which will be exhibited at JEC. Hence, the lightweight construction potential of high-performance fibres can be fully exploited.

A successfully established development are partially flowable 2D textile reinforcement fabrics that are continuously manufactured in one single process step. For this purpose, the entire process chain was developed at the ITM, which allows a cost-effective and high-volume production of load-bearing thermoplastic 3D FRP components with continuous fibre reinforcement between shell and stiffeners.

At JEC 2023, the ITM will also present a partially embedded textile latice girder as reinforcement for carbon concrete applications, which was produced by means of an innovative textile manufacturing process based on the multiaxial warp knitting technology. Through the development of a customized warp insertion, manipulation and take-off system as well as appropriate shaping methods, it is now possible to produce tailored textile semi-finished products, e.g. for use in wall and ceiling panels. These textile latice girders represent a resource-saving alternative to conventional steel girders due to the reduced among of concrete required and the additional cavity for media and cable guidance.

The integration of textile actuators and sensors in FRP provides structures with additional functionalities. The research and application of such interactive FRP with different matrix materials (e.g. with thermoset, elastomer or concrete matrix systems) for structural health monitoring or adaptive systems is one of the key research areas of the ITM.

Moreover, the development and implementation of innovative yarn constructions based on recycled high-performance fibres (e.g. rCF, rGF, rAR) for sustainable FRPs is successfully promoted at ITM. By use of a special carding machine, recycled fibres are opened up, separated and joined to form a wide, uniform ribbon. Subsequently, innovative hybrid yarn constructions made of evenly mixed recycled high-performance and thermoplastic fibres with variable fibre volume fractions can be manufactured by means of various spinning technologies. Selected yarn constructions and components will be showcased at JEC.