The Nordic countries’ first industrial end-of-life textile refinement plant will open in Paimio in 2021.

Rester Oy, which is developing the plant in Paimio, recycles companies' end-of-life textiles, and Lounais-Suomen Jätehuolto Oy (LSJH), which will hire a production area at the same facility, processes households' end-of-life textiles. The plant will process 12,000 tonnes of end-of-life textiles every year, which represents about 10% of Finland’s textile waste.

The textile industry’s end-of-life textile problem is intolerable. Natural resources are increasingly used to manufacture products, but these materials are lost at the end of their life cycle. About 100 million kilograms of textile waste are generated annually in Finland alone. Reusing this material could reduce the textile industry’s carbon footprint and significantly reduce the use of natural resources.

Rester Oy and LSJH will drive the textile sector towards a circular economy and begin processing textile waste as an industrial raw material. The Nordic countries’ first industrial end-of-textile refinement plant will open in Paimio in 2021. The 3,000-square-metre plant is being developed by Rester Oy, which recycles companies' end-of-life textiles and industrial waste materials. LSJH, which processes households’ end-of-life textiles on its production line, will hire part of the plant.

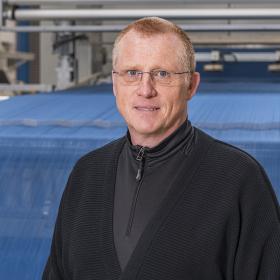

Outi Luukko, Rester Oy’s board chair, says, “The processing plant will begin a new era of textile circular economy in Finland. As industry pioneers, we are launching a system change in Scandinavia. The transition of the textile industry from a linear model to a circular economy is essential, as virgin materials cannot sustain the current structure of the textile industry. And why should it, when there is so much recyclable material available?”

From the perspective of Rester Oy’s main owner, work clothing supplier Touchpoint, the circular economy plant not only represents resource efficiency, but is also necessary from the perspective of the entire life cycle of a responsible work clothing collection.

Luukko adds, “Finding a local solution to a global problem is a huge leap in the right direction and raises Finland's profile as a pioneer of circular economy."

The future plant will be able to process 12,000 tonnes of end-of-life textiles annually, which represents about 10% of Finland’s textile waste. Both production lines produce recycled fibre, which can be used for various industrial applications, including yarn and fabric, insulating materials for construction and shipping industries, acoustic panels, composites, non-woven and filter materials, and other technical textiles, such as geo-textiles.

LSJH is piloting a full-scale refinement plant

LSJH has launched a pilot production line for processing households' end-of-life textiles. Unfortunately, consumers' end-of-life textiles are heterogeneous, making them a challenging raw material for further processing. Before processing, the textiles are sorted by material into various fibre classes using optical identification technology developed by LSJH and its partners. This ensures the quality of the raw material and the resulting fibre products.

Jukka Heikkilä, managing director for Lounais-Suomen Jätehuolto, explains: “On the basis of the experiences gathered from the pilot project, Lounais-Suomen Jätehuolto is preparing a full-scale refinement plant in the Turku region. As soon as 2023, the plant will process Finnish households' end-of-life textiles. The project involves all waste treatment plants owned by Finnish municipalities.”

Paimio has ambitious goals for circular economy companies

Rester’s initiative aims to create a circular economy cluster in Paimio that combines the processing and reuse of end-of-life textile fibres. Paimion Kehitys Oy, which is owned by the City of Paimio and the local association of enterprises, supports the development of circular economy companies in Paimio.

Mika Ingi, managing director for Paimion Kehitys Oy, says, “We want to step out of our traditional municipal role and create significant added value for everyone taking part. That is why we are involved in the development of a new modern service model based on ecosystem thinking. We are piloting the textile cluster, followed in the coming years by clusters focusing on plastic, construction, and energy. The aim of our service is to support and help develop new profitable business by bringing circular economy companies and their potential customers to innovate together."

The foundation stone of the processing plant was laid today (18 August 2020). The processing plant will begin operations in February 2021.