adidas and IVY PARK announce IVY HEART, a capsule collection

adidas and IVY PARK CEO Beyoncé announce IVY HEART, a new capsule collection inspired by love , just in time for Valentine’s Day, from the ongoing adidas x IVY PARK creative partnership.

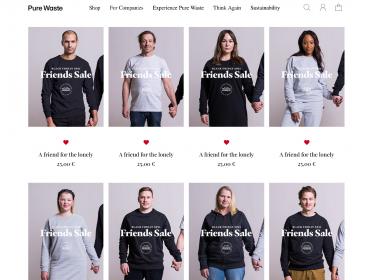

As with previous adidas x IVY PARK offerings, this latest collection features distinct looks with inclusive and in gender-neutral sizing in fashion styles, performance gear, footwear, and accessories. The line is available online at adidas.com on February 9th and February 10th in selection stores globally.

The Campaign

The campaign focuses on the guiding thematic color behind the collection. In the Western world, red is commonly associated with love , romance and sensuality. While in the East, red is attributed to good fortune and joy. Wherever you are, it’s clear that this color represents positivity. The concept is centered around bringing people together from all different backgrounds through this one color that’s sentimental to so many. This theme is illustrated through enhanced lighting, bold yet minimal production design, elevated styling and most importantly the international cast. Cultural cues from specific iconography and symbols are explored in visual motifs with sensitivity and intention. IVY PARK pays homage to various cultures inspired by this color, incorporating red through a futuristic yet authentic lens.

The Collection

No matter how you define it, love - most importantly love of one’s self - is at the core of IVY PARK ’s newest drop. Bold and sexy looks are an integral part of IVY HEART, which is aptly decked out in a spectrum of vibrant reds, playful pinks, and nuanced neutrals. In colors that include Candy Paint (Shock Pink), Lipstick Smudge (Red), Raspberry Beret (Power Red), Red, Red Whine (Cherry Wood) and Cheeks (Off-White), the line is punctuated by tactile materials like velour, ribbed knit, and faux latex. IVY PARK ’s latest collaboration with adidas is further complemented by performance fabrics and graphic prints, allowing ample designs to mix-and-match from work out to night out.

The capsule collection’s design touchpoints are rooted in Beyoncé’s love of athleticism and fashion, merged with adidas’ performance and innovation. The references culminate in a collection of silhouettes that are sporty, stylish, and above all, unique. Conceived around three pillars of foundation, active, and fashion, IVY PARK ’s latest collection is highlighted by the Velour Dress and Tracksuit, Faux Latex Puffer, Pique Jumpsuit and Sequin Duster. Accessories include a 5-Panel Hat, a clutch and a Heart-Lip Belt Bag.

Footwear consists of both on-the-court and off-duty models. The range is highlighted by a new iteration of the classic Stan Smith sneaker in Cheeks (Off-White), with a rubber dipped midsole. Additionally, the collection introduces a new silhouette, the IVP Superstar Plim, a mule style shoe inspired by the iconic adidas Superstar in Cheeks (Off-White). The line also features a new colorway of the IVP Savage sneaker in Cheeks (Off-White), a IVP swim slide in Lipstick Smudge (Red) and the Ultra boost in Candy Paint (Shock Pink).

adidas