Kornit expands digital textile production in Turkey with Matset partnership

Kornit Digital has announced its partnership with Matset (Turkey) as it continues to broaden its market presence.

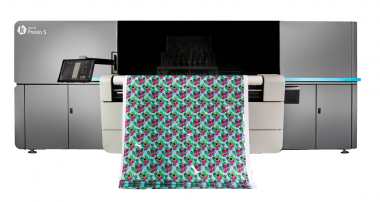

Delivering digital textile production-on-demand solutions to the Turkish market

With over 45 years of experience, Matset has a long-standing reputation as being a pioneer of innovation in the printing industry. After the first meeting, Kornit and Matset were quick to recognize how their partnership would effectively accelerate the development of the Kornit brand and solutions in the Turkish market. The deal will see Matset sell and deliver after-sales support for all Kornit textile solutions, including both direct-to-garment and direct-to-fabric product lines, particularly for t-shirts, activewear, denim, fashion, beachwear, home textiles, and fabrics.

Doğu Pabuççuoğlu, General Manager at Matset, explains the collaboration combines the digital leading vision of Matset with the market awareness and quality of Kornit’s products: "With Kornit’s production systems, we have made an important addition to our product portfolio. We were able to quickly build a roadmap and are sure the market share will increase very rapidly in the near future. With Kornit’s reliable and creative solutions and our well-known and engaged distribution network, we will provide customers with a strong sales and support service.”

pr4u