Freudenberg: Technical packaging textiles with less CO2 emissions

By using a high share of recycled content in its Evolon® materials, Freudenberg Performance Materials (Freudenberg) offers technical packaging textiles with a carbon footprint decreased by 35%. An independent LCA study showed additional benefits such as energy resource savings and lower water use. Furthermore, Evolon® fabrics provide sustainability benefits over the packaging entire life cycle thanks to high end performance and durability.

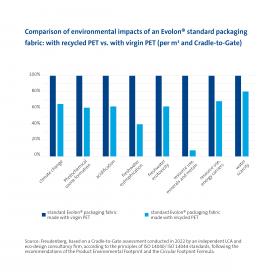

By replacing virgin PET with recycled PET, the cradle-to-gate carbon footprint of Evolon® packaging textile materials decreased by 35%. This is the result of a study by an independent LCA and eco-design consultancy firm, which made a Cradle-to-Gate assessment of several Evolon® products using virgin PET or recycled PET. The study was finalized in 2022 and conducted according to the principles of ISO 14040/ ISO 14044 standards, following the recommendations of the Product Environmental Footprint and the Circular Footprint Formula.

Evolon® microfilament textiles have a small carbon footprint because their manufacturing process uses low CO2 energy sources. The fabrics are lightweight and can be reused throughout entire production programs, e.g. of a car model when it is about the automotive industry. Furthermore, the new Evolon® RE fabrics contain up to 85% of recycled PET which is produced in-house out of post-consumer PET bottles.

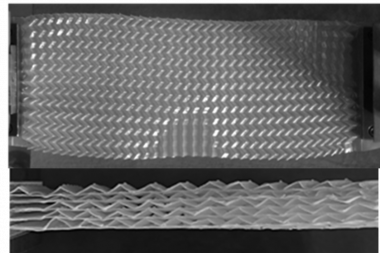

Evolon® textiles are suitable for reusable technical packaging, which eliminate the use of thousands of disposable packaging materials. Evolon® fabrics offer scratch-free, lint-free, high-end surface protection for molded plastic parts, painted parts and other sensitive industrial and automotive parts during transport. This contributes to lower the scrap rate of parts and provide both financial and ecological benefits. By using Evolon® reusable packaging to transport highly-sensitive parts, customers can increase their efficiency and save resources.

Freudenberg Performance Materials