Archroma partners with University of North Carolina Greensboro on color expert education

Archroma, a leader in specialty chemicals towards sustainable solutions, has announced the launch of a collaboration with the University of North Carolina Greensboro (UNCG) and its Consumer, Apparel, and Retail Studies (CARS) department, aiming to further the education of its students in the area of color management expertise.

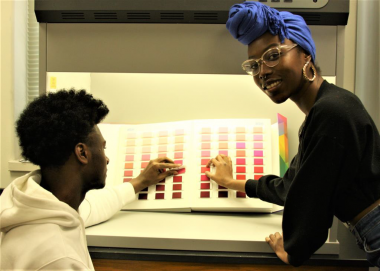

As per the agreement, Archroma will donate its color management tools for their design projects, gaining hands-on expertise that equips them for successful careers in the fashion and textiles industries.

The students will have access to a complete set of the ready-to-use color library developed by Archroma for cotton and polyester. The library, well known among fashion designers and stylists as the Color Atlas by Archroma®, which was launched in 2016 to provide off-the-shelf color inspiration that can be implemented in production with just a few clicks.

Today, the Color Atlas contains 4’320 colors applicable on cotton poplin, almost the double compared to similar tools available to textile and fashion specialists, and 1,440 colors on polyester.

Beside the physical Color Atlas library, the students in the CARS program will also have access to the full digital files for use in the industry-leading 3D fashion design and development software Browzwear VSticher.

The students will be able to use the Color Atlas books and the digital data as a color selection resources to use in a variety projects and assignments.

Archroma / EMG