ISKO supports designers at London Fashion Week

ISKO provided their latest innovation in material science to British designers, Priya Ahluwalia, Masha Popova, Chet Lo and Aaron Esh, for the London Fashion Week SS24 season.

Alongside supplying their latest denim fabrics, ISKO opened its doors to its London-based product development centre, Creative Room London, for finishing and washing of their final designs as well providing expertise and knowledge in denim design and construction.

Priya Ahluwalia

For Ahluwalia’s Spring Summer 24 collection, entitled Acknowledgements, Creative Director and founder Priya Ahluwalia’s research led her on a journey of creative rediscovery.

ISKO’s Ctrl+Z fabric, which is made entirely from recycled and regenerated fibres, was used to create the flower motif denim showcase within 3 looks across jeans and jackets. This development contains no virgin cotton and uses a minimum of 60% recycled materials and the remainder is regenerated cellulose fibres while still giving a look and feel identical to traditional denim and speaks to Ahluwalia’s ongoing commitment to sustainable design and business practices.

Chet Lo

This season, Chet Lo took an active stand in reclaiming the power lost during his youth, healing the childhood wounds inflicted by a society that sidelined differences instead of celebrating them.

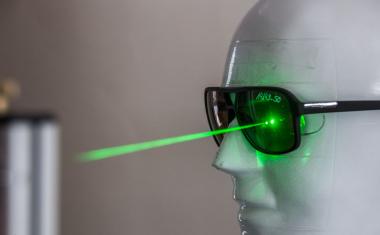

ISKO’s Ctrl+Z fabric and specialist lasering techniques from ISKO’s Creative Room was used across three looks featuring signature Chet Lo erotic laser prints across denim bottoms.

Aaron Esh

The SS24 season marked the brand’s debut at London Fashion Week, a homecoming of sorts for Esh, who was born and raised in the heart of the British capital, studied at Central Saint Martins and became a finalist at the LVMH Prize earlier this year. The early impulses of Aaron Esh remain steadfast: clothes that combine establishment rigour with the rebellious spirit of youth culture, devotedly crafted for a generation who feels somewhere in-between.

Aaron created bootleg denim ripped jeans made entirely from ISKO Denim using R-TWO50 fabric, which comprises a minimum of 50% pre and post-consumer recycled content. The designer noted the addition of denim accompanied by leathers add a new level of depth to their latest collection.

Masha Popova

Masha Popova’s sophomore catwalk outing, MONSTER was a “seasonless” offering that combines Autumn Winter 2023 and Spring Summer 2024.

Masha continued her obsession with denim manipulation, using various finishings including over-dyeing, flocking, patchwork, scratching and fraying in a variety of colours from vibrant green to silver across jeans, tops and jackets, all developed with the help of ISKO’s Creative Room, London.

ISKO