Oerlikon: Manual lever now even more ergonomic

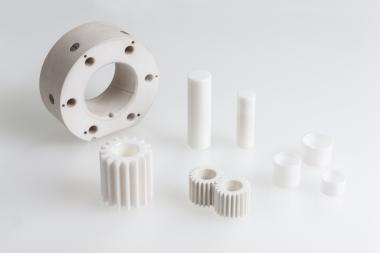

Finer adjustment of the yarn suction force, lower compressed air consumption for the same yarn tension, smooth, ergonomic compressed-air valve – all promises fulfilled by the modernized AS H 32 and AS H 38 yarn suction devices.

Also known as hand injectors, these yarn suction devices are standard components of all spinning positions. The AS H 32- and AS H 38-series are high-performance hand injectors with lower compressed air consumption for the same yarn tension. This is made possible due to the higher yarn suction forces, particularly in the case of the AS H 38 series. In addition to this, string-up without ‘ramp-up’ is possible in certain applications. Also new is a smoother, more ergonomic compressed-air valve, which makes deploying the yarn suction devices more comfortable for users. Furthermore, the required yarn suction force can be adjusted more finely.

The new ‘high-performance devices’ have been designed for applications that require a particularly high suction performance. For several months now, they have been successfully operating in pilot projects within the context of a BCF yarn application in Europe and a tape yarn system located in the US.

Oerlikon