Iluna: Sustainability in the lace manufacturing industry

Since 2014, Iluna Group Srl stands out for braiding together the values of beauty, innovation and responsibility.

The company achieved this with Iluna Lab, a cutting-edge research and development centre where laces are conceived and engineered to become sustainable ingredients for the contemporary wardrobe.

The smart values are attested by the STeP - Sustainable Textile Production by Oeko – Tex® certification for its ethic approach. “We are also the first lace producer to have gained the GRS - Global Recycled Standard for transformed products, and whose products are all certified OEKO-TEX® Standard 100.” Comments Walter Colombo, Technical Director at Iluna Group Srl.

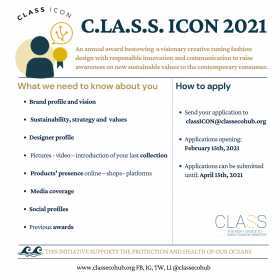

Moreover, in recognition of the great value of responsible innovation, Iluna Group is now officially a partner of C.L.A.S.S., the international ecohub founded in 2007 by Giusy Bettoni, a reference point in the fashion and textile sector for all those who want to make fashion smarter.

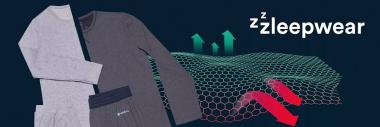

Now the company announces two important collaborations with Néné Paris and NOO, “two booming French brands which have intercepted and share our values and vision for sustainability where beauty and innovation are key”.

Néné focuses on preserving natural resources using only upcycled fabrics or fabrics made with recycled fibers. Each and every step of the production is entirely made in Europe.

French independent designer brand NOO creates exquisite lingerie, timeless ready-to-wear garments and bold cut swimwear and bodysuit for women. The brand pays extreme care to aesthetics and details at every step of the production process, from sourcing materials to waste reduction, choosing factories and using recyclable packagings.

GB Network