Freudenberg: Protection and Flexibility for Workwear

Freudenberg Performance Materials (Freudenberg) offers a range of efficient interlinings, tapes and thermal insulation materials for workwear and protective clothing. The materials not only withstand diverse kinds of strain they are exposed to in everyday work and washing procedures but also offer great comfort.

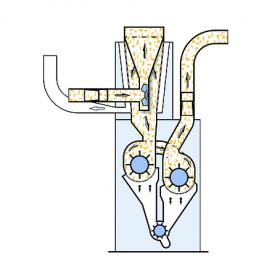

Innovative materials and manufacturing technology

The nonwoven and woven interlinings and tapes stand out due to a number of features, such as increased stability, elasticity, abrasion resistance and wind-blocking properties. Thanks to the sophisticated adhesive technology used by the manufacturer of technical textiles, some products are especially resistant and durable.

Highly flexible and resilient interlinings as well as Freudenberg comfortemp® thermal insulation materials are used for protective clothing, and they do not only protect the wearer from danger but also ensure the wearer’s comfort in any kind of weather. Furthermore, hem and edge stabilisation tapes ensure optimal fit and reflective tapes provide additional safety.

Active contribution to sustainability

Many products of the Freudenberg Workwear Range consist of a high percentage of recycled polyester coming from post-consumer PET bottles.

Freudenberg Freudenberg Performance Materials Protective Textiles Workwear protective personal protective equipment Sustainability

Freudenberg Performance Materials Holding SE & Co. KG