Intertextile Shanghai Home Textiles 2020 opens next Monday: new digital tools complement in-person meetings

Asia’s leading trade platform for the home and contract textile industry, Intertextile Shanghai Home Textiles, is ready to welcome over 600 exhibitors to China’s commercial hub from 24 – 26 August. As China’s economy continues its recovery, the upcoming fair will serve as a key platform for the industry to reconnect and prepare for the seasons ahead. Taking consideration of current international travel restrictions, Intertextile has launched a brand new online business matching platform, enabling participation for those who cannot travel to Shanghai.

Ms Wendy Wen, Senior General Manager of Messe Frankfurt (HK) Ltd commented: “2020 has been a difficult and unpredictable year for every business and industry across the world, so we are pleased to be providing a platform for the home textile industry to connect and recover from the coronavirus pandemic. Intertextile Shanghai Home Textiles is the first physical trade event for the sector held by Messe Frankfurt since January, so we hope that the fair assists the sector to join forces and overcome this challenging year together.”

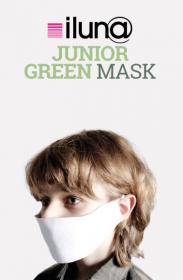

Ms Wen continued: “Our first priority is to create a clean and hygienic space for all participants to source and network. To achieve this goal, the fair will implement extra health care and hygiene precautions onsite. On the other hand, we are aware that a number of travel restrictions are still in place across the world. With this in mind, Intertextile will offer a series of online services for those who are unable to travel to Shanghai, allowing the fair to reach as wide an audience as possible.”

2020 fair highlights

To provide buyers with greater efficiency, the fair, which covers four halls, will be divided clearly by product categories: Household Hall (hall 3), International Brands / Upholstery Hall (hall 4.1), Brand Fabrics Hall (hall 5.1) and Sofa Fabrics Hall (hall 6.1).

In addition, the Contract Business 360° concept will return this year, with over 40 premier upholstery exhibitors presenting their latest textile products and furnishing solutions for contract use. Exhibitors include Guangzhou Yuanzhicheng Home Textile, Haining Julai Textile, JAB, Morgan Shanghai, Symphony Mills, Suzhou Roufang, Ter Molst International, Zhejiang Hexin and Zhejiang Maya Fabric. Furthermore, top brands such as Agmamito from Poland and Wollsdorf Leather from Austria will be exhibiting for the first time at Intertextile.

Online business matching platform offers new sourcing landscape

Although face-to-face interaction is irreplaceable, a virtual complement has become more important as a result of the worldwide pandemic. To support the industry during these unprecedented times, Intertextile has launched a brand new online business matching platform. With this free service, participants are able to source and network at their fingertips. The virtual platform will offer many new features including:

- Easy sourcing: exhibitors are categorised by product groups including Sofa / Decorative Fabrics, Curtains and Accessories, Bedding and Finished products, Shading and Accessories, and Editors

- Live-streamed product presentations of exhibitors

- Smart recommendations: pre-selected exhibitor lists will be provided to buyers based on their personal preferences and interests

- Convenience: participants are able to use the service through computers or portable devices without the need to download any software

High quality fringe programme covers comprehensive topics

The fair’s event programme will once again provide the industry with the latest trends and insights in four topics: Design Inspiration, Business O2O, Textile & Technology and Industry Empowerment. One of the highlights will be the 2021 Intertextile Trend Forum, led by Shen Lei, the Chinese representative of the Intertextile International Lifestyle Trend Committee. The forum will bring together five prominent Chinese designers including Ben Chen, Ben Wu, Meng Ye, Paul Pang and Xie Ke, who will delve into the theme of 2021 Intertextile Trends–“BOUND”, as well as the Chinese market conditions. The event will be held on day 1 of the fair, from 14:00 – 17:00 in hall 5.1 booth C18, and streamed live online.

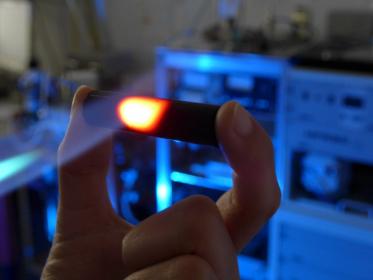

Another not-to-be-missed event is the Ride the Storm – Home Textile Digital Printing Forum, which will include an array of educating seminars that cover the latest digital textile printing trends and technologies. The forum will be held on day 2 of the fair, from 13:20 – 17:20 in hall 3, booth M12.

Furthermore, joining forces with Tmall Global, the largest cross border B2C online retail platform in China, the fair will host a series of seminars delivering the solutions and strategies for industry digitalisation during the afternoon of day 1. In addition, the well-received Furniture & Home Textile Direct Negotiation Event will return to provide an excellent opportunity for furniture companies and fabric brands to collaborate.

Additional health care and hygiene precautions will be in place

As trade fair co-organisers, Messe Frankfurt’s number one priority always remains the health and safety of fairgoers. To maintain a clean and hygienic environment for visitors and exhibitors to meet in, extra measures will be in practice at the fair. These include: real-name registration, onsite temperature checks, frequent sterilisation of public areas and distancing measures for forum / seminar audiences, amongst others.