ROICA™ presents new developments for contemporary consumers

As the role of lingerie in fashion and athleisure continues to augment, the desire for garments that will meet a new set of values for contemporary consumer lifestyles will flourish.

ROICA™ - the pioneer of innovative stretch fibres, took this year’s Interfilière visitors on an inspirational journey, aimed at encouraging weavers, designers and brands to “engineer” their portfolio of products in new and exciting ways. The company sets a whole new standard in how creativity and responsibility can come together for a new generation of wardrobe solutions dedicated to the contemporary consumer, carving out a new kind of fashion future.

Below some unique developments born from the collaboration among ROICA™ and key premium brands:

COSABELLA produced by Collezioni SRL: The brand sells in over 100 countries, with a premium collection of 2000 styles for every sector of lingerie and leisurewear. Latest styles use a delicate floral lace by Tessitura Colombo Antonio made with ROICA™ V550 belonging to the ROICA Eco-Smart™ family for their more luxurious upscaled lines.

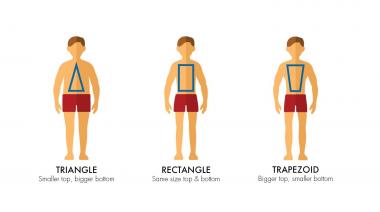

Livy selects Iluna Group’s contemporary graphic stretch lace with ROICA™ EF for the precious “BELLAGIO” line that includes a soft triangle bralette, a padded bra, a brief and a body for optimal comfort. The must-have range has a stunning aesthetic which represents the unique appeal of this lifestyle brand.

Sarah Borghi: the worldwide known brand of luxury Italian fashion hosiery, tights, and socks. They've dedicated more than 40 years scrutinizing the finest yarns and evolving technologies and breathing flawless life into their unique range of luxurious fashion. Today, Gizeta Calze S.r.l., owner of this brand, has developed the first line made out of sustainable ingredients that will be launched at the ROICA™ booth during Interfilière. The collection, developed in Italy by Almatex, blends together key smart fibers such as ROICA™ EF and Q-Nova®, and ROICA™ V550 with AMNI SOUL ECO®.

Vitamin A: the Californian brand offers a unique swimwear line rooted in female empowerment. Vitamin A’s beachwear is made with the finest materials and finishes, ensuring a product that will fit and wear beautifully for years to come. Among the incorporated more sustainable high-performance fabrics shines a unique jacquard development by Maglificio Ripa with a 3D texture made with the GRS certified premium responsible stretch ROICA™ EF and Q-NOVA® by Fulgar. Vitamin A is a member of 1% For The Planet and donate to environmental organizations who work to protect our oceans.

Wolford was one of the first brands to explore the real value of ROICA™. Known for its exceptional European Skinwear including legwear, lingerie and bodywear, the company has been striving to develop fully degradable items at the end of the product lifecycle. On top of last year’s award for being Cradle to Cradle Certified™ at GOLD Level certification for the biological cycle, Wolford was also recognised for its technical cycle using Econyl® yarn made by Aquafil (always blended with ROICA™ V550).

Each brand Partner brings a different yarn story firmly into the limelight, and all feature ingredients from the ROICA™ portfolio of yarns respecting the company’s commitment to ‘responsible innovation’, and which all boast important sustainable certifications.

ROICA™ Fashion Mode Collezioni SRL Vitamin A Sarah Borghi Wolford Livy ILUNA Group, ROICA, partnership, certified materials

GB Network Marketing & Communication