Avgol® at INDEX™ 23

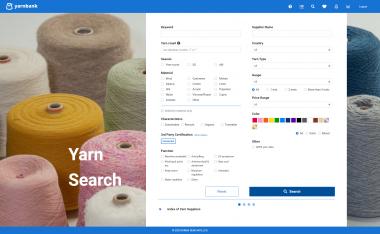

Avgol®, a manufacturer of high-performance nonwoven fabric solutions, will use this month’s INDEXTM exhibition in Switzerland to showcase how it has a laser focus on delivering against sustainability objectives to safeguard the future.

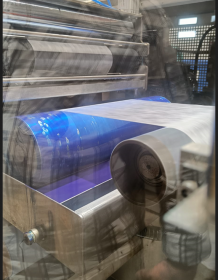

Together with its sister companies from Indorama Ventures Limited (‘IVL’), Avgol will be presenting biotransformation capable fibers, spunbond, meltblown and SMS for diversified end-use markets at the event. Avgol will present and be available to discuss with visitors how this developing technology and the company’s other related products can help businesses achieve their 2030 sustainability goals.

Avgol will also highlight the latest solutions since recently announcing its collaboration with Algaeing™. Avgol uses patented algae bio-based formulations for colorants in its products, combining a unique environmental solution for modifying the aesthetic qualities of materials with Avgol’s ongoing commitment to sustainable polyolefin based spunbond and meltblown fabrics.

Avgol Indorama Ventures Limited nonwovens Fibers Meltblown spunbond technology Algaeing™

Avgol / PHD Marketing Ltd