Circ Launches Circ-Ready Community

Circ®, a US-based textile-to-textile recycling innovator, announced the launch of Circ®-Ready, an exclusive community of global supply-chain partners who have demonstrated their ability to make high-quality, better-for-the-planet solutions for fashion brands using Circ materials. The inaugural Circ-Ready partners include AGI Denim, Foshan Chicley Textile Co., Ltd., Giotex, Marubeni Corporation, MAS Holdings, PYRATEX®, Selenis, SHINJINTEX, Soorty Denimkind, Tainan Spinning Co., Ltd., and Taiwan Textile Research Institute (TTRI).

The Circ-Ready community is a selected group of partners who have a proven positive track record and commitment to working with Circ recycled products and have been individually evaluated for industry success. Circ-Ready partners work alongside the Circ team of experts to adequately test and utilize Circ fibers, exceeding quality standards from end to end. To promote transparency and ensure the integrity of Circ products, each Circ-Ready partner provides a commitment to relevant best-in-class certifications for recycled products.

Consisting of processors, manufacturers, and other vital industry players across tiers 1-4, each Circ-Ready partner has undergone a testing process to replace virgin inputs with Circ’s products, proving the ability to utilize Circ products in their existing operations and produce premium materials as a result. Being a member of the Circ-Ready community provides partners the opportunity to work with pilot-stage Circ products, receive ongoing support from Circ’s technical experts, and be among the first recommended by Circ when brands and partners seek to utilize Circ material.

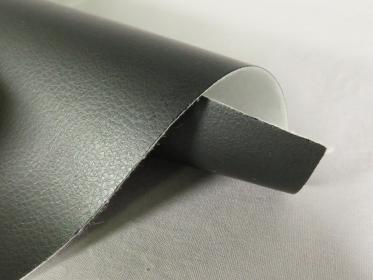

Circ is a leader in blended textile-to-textile recycling, a known challenge for the industry. Each year, tens of millions of tons of polycotton textile waste is landfilled or burned because existing recycling solutions cannot separate the plastic from the natural fiber and recover both materials. Circ’s innovative recycling technology is the only platform to successfully separate polycotton blended textile waste and recover both cellulosic and synthetic fibers. Circ’s primary fiber outputs are regenerated Circ Lyocell and Circ Polyester from textile waste.

Circ