Solvay: Educational alliance with MIT and Fermi High School

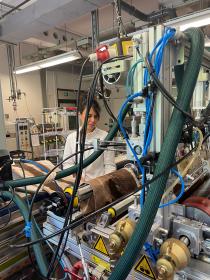

Solvay awarded a scholarship to facilitate an educational alliance between the Massachusetts Institute of Technology (MIT) and Fermi High School in Cecina. The initiative unfolded during an event held at Solvay's Rosignano site in Italy, providing a platform for students and faculty. Through this partnership, 200 Fermi High School students participated in STEM* and digital lessons from MIT's Global Teaching Labs project, emphasizing the teaching of scientific disciplines by the American university.

Beyond the scholarship award ceremony, students received a tour of Solvay's factory in Rosignano. The tour highlighted the company's dedication to safety, sustainability, and bridging the gap between academia and industry challenges. The experience illustrated the practical application of academic studies in an industrial context, showcasing Solvay's advanced control procedures, safety protocols, technological innovations, digital transformation efforts, and sustainability measures.

Discussions during the event included key sustainability topics such as water conservation, energy efficiency, waste management, and Solvay's commitment to promoting a balanced work-life culture and diversity within the workplace.

This collaboration aligns with Solvay's global Corporate Citizenship program. Through this program, Solvay supports individuals and communities, channeling efforts to tackle worldwide societal challenges through strategic investments in education, sustainability, and local community initiatives.

*STEM stands for science, technology, engineering and mathematics

Solvay