Zerobarracento brings the Made in Italy zero-waste to Budapest Fashion Week

For the third consecutive year, the Italian brand Zerobarracento was selected to embody the excellence of Italy at the Budapest Fashion Week. On November 14th, Zerobarracento will show on runway S/S 2019. The concept of connection to a fashion garment, and the idea of creating pieces to last is fundamental to this brand. 0 means: zero waste, reduced pollution, and reduced emissions. 100 means: 100% quality, Made in Italy, sustainability and transparency of the production. Patterns are developed with zero-waste techniques, that eliminates textile waste at the design stage, adopting a zero-waste design approach reduces textile waste and the demand on natural resources. The pieces are 100% made in Italy, created with premium sustainable and traceable materials.

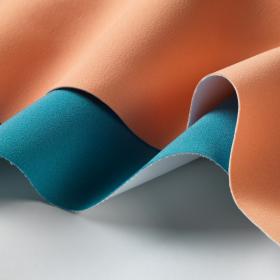

Camilla Carrara, CEO and designer of Zerobarracento, describes the collection as follows: "garments are created with the GOTS certified Bacx™ by Centro Seta organic silks sourced from C.L.A.S.S. e.commerce and the Newlife™ transformed polyester. Shapes and colours were inspired by a Malaysian trip: simplicity and nature are blended giving life to saturated colours".

We are pleased that the collaboration with the Budapest Fashion Week lasts over time and is positive to see the growing interest for the issue of sustainability by consumers of this country.

GB Network Marketing & Communication