adidas Originals and Edison Chen announce Partnership

adidas Originals and Edison Chen announce their global partnership, adidas Originals by Edison Chen, as Chen makes his return to the brand to begin a new era of collaboration that will redefine creative innovation and build a cultural legacy for the future.

Chen is the Founder and Creative Director of global lifestyle brand CLOT, which is celebrating its 20th anniversary this year. After moving from Vancouver to Hong Kong in his youth, the clash of East meets West began for him as he adapted to the exposure to different cultures. His experiences and new perspectives opened his eyes to globalism and started to lay the foundation for what would eventually become CLOT.

For his partnership with adidas Originals, Chen will bring an innovative vision and creative prowess to introduce exclusive collaboration styles, leveraging adidas’ extensive archive and history in the process. With a focus on fostering cultural exchange between the East and West, adidas is partnering with Chen to introduce collections that push boundaries and defy the norms with his thought-provoking designs.

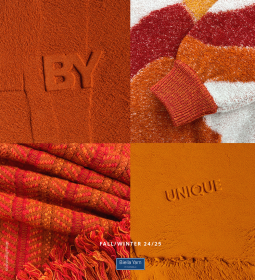

Celebrating the shared commitment to creative innovation between adidas Original and Edison Chen, the “Change The Generation” collection explores three distinctly different styles ranging from ultra-lifestyle to formal dress and active/streetwear bringing to life a collection that can be explored individually as well as a collision of the three lifestyles together.

Pieces from the collection will start becoming available in January 2024.

adidas AG