Lenzing: State Prize for Innovation with sustainable nonwovens technology

- On October, 20th, 2020, the State Prize for Innovation was awarded to the Lenzing Group for their LENZING™ Web Technology.

- Lenzing thus received the highest award for particularly innovative achievements in Austria.

Lenzing – On Tuesday, October 20, 2020, the Lenzing Group was awarded the coveted “State Prize for Innovation”. Lenzing emerged as the winner with its project LENZING™ Web Technology and thus received the highest recognition for particularly innovative achievements in Austria. The novel process combines fiber and nonwovens production in only one step, setting new standards in terms of efficiency, circularity and ecological sustainability. Margarete Schramböck, Federal Minister for Digital and Economic Affairs, presented the award to Gert Kroner, Vice President Global Research & Development.

“This award is a great recognition of our work. Our goal is to grow continuously with sustainable innovations and to look beyond our fibers, to the needs of our customers and partners and to the needs of consumers worldwide. With the LENZING™ Web Technology we have created an exciting and promising solution for eco-friendly products in line with our corporate strategy sCore TEN and support consumers in their daily needs in a sustainable way”, says Stefan Doboczky, Chief Executive Officer of the Lenzing Group.

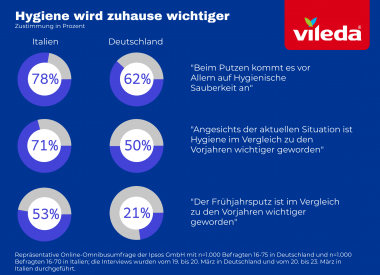

Biodegradable nonwovens for a clean environment

The pollution of the environment by plastics is one of the most urgent problems of our time. Every day, millions of hygiene products and wipes around the globe end up in garbage and sewage. Most of them consist of up to 80 percent polyester or other fossil, non-biodegradable materials and therefore pollute the environment. With the LENZING™ Web Technology, Lenzing has developed a patented technology to counter this problem: Sustainable and eco-friendly nonwovens are produced from the renewable raw material wood. These are not only plastic-free, they also score points for their particularly high environmental friendliness. “Thanks to a unique self-bonding mechanism, in which the filaments bond with each other during the spinning process, binders, which are found in many nonwovens, are no longer needed. As a result, the nonwovens produced with LENZING™ Web Technology are 100 percent biodegradable and do not pollute either humans or the environment”, says Gert Kroner, Vice President Global Research & Development of the Lenzing Group.

The Austrian State Prize for Innovation is awarded annually by the Federal Ministry for Digital and Economic Affairs to the most innovative Austrian company. In 2020, the competition took place for the 40th time.

Lenzing Group Nachhaltigkeit LENZING™ Web Technology Staatspreis Innovation Digitalisierung

Lenzing Aktiengesellschaft