Cellulose Fibres: New Technologies for Pulp, Fibres and Yarns

- Session "New Technologies for Pulp, Fibres and Yarns"

Cellulose fibres are a true material miracle as they offer a steadily expanding, broad range of applications. Meanwhile markets are driven by technological developments and policy frameworks, especially bans and restrictions on plastics, as well as an increasing number of sustainability requirements. The presentations will provide valuable information on the various use-opportunities for cellulosic fibres through a policy overview, a special session on sustainability, recycling and alternative feedstocks, as well as the latest developments in pulp cellulosic fibres and yarns. In addition, examples of non-wovens, packaging and composites will offer a look beyond the horizon of conventional application fields.

The extensive fifth conference session, “New Technologies for Pulp, Fibres and Yarns”, includes the participation of eight speakers and promises the reveal of various innovations and new approaches. These address the processing of pulp, fibres and yarn, with the aim of realizing most sustainable and efficient solutions. The broad spectrum of topics ranges from processing cellulose with ionic liquids, material farming and chemical modification of pulp to functionalised fibres for feel-good textiles.

Speakers of the Session "New Technologies for Pulp, Fibres and Yarns"

- Antje Ota - Deutsche Institute für Textil- und Faserforschung (DITF) (DE): The Versatility of the HighPerCell® Technology for Cellulose Filament

- Carlo Centonze - HEIQ (CH): HeiQ AeoniQ – Cellulose Yarn Focussed on Climate and Circularity

- Manuel Steiner - LIST Technology AG (CH): Cellulose Dissolving Technology Platform

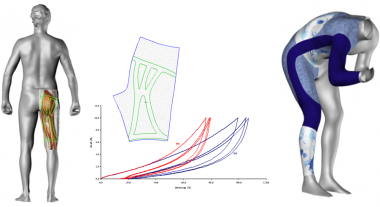

- Dominik Mayer - Kelheim Fibres (DE): Functionalized Viscose Fibres for Wellbeing Textiles: How Infrared Celliant® Viscose supports a Healthy and Sustainable Lifestyle

- Michael Sturm - TITK (DE): Method for the Evaluation of the dissolution Power and dissolution Quality of Cellulosic Raw Materials dissolved in New Ionic Liquids

- Kaoutar Aghmih - Hassan II University (MA): Rheology and Dissolution of Cellulose in Ionic Liquid Solutions

- Ofir-Aharon Kuperman - Weizmann Institute of Science (IL): Material Farming and Biological Fabrication of Cellulose Fibers with Tailored Properties

- Taina Kamppuri - VTT Technical Research Center of Finnland (FI): Chemically Modified Kraft Pulps to Improve the Sustainability of Regenerated Fibres

International Conference on Cellulose Fibres Fibers pulp production DITF HeiQ LIST Technology AG Kelheim Fibres TITK Hassan II University Weizmann Institute of Science VTT Technical Research Center of Finnland

nova-Institut GmbH