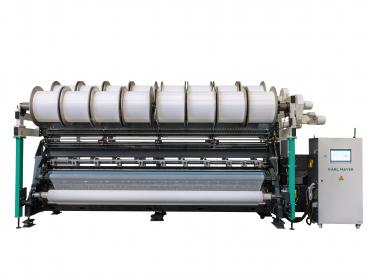

KARL MAYER launches new Elastomeric Raschel machine

KARL MAYER launches its RE 4-1, a new Raschel machine for the efficient production of highly elastic textiles. With this newcomer, KARL MAYER is expanding its Elastomeric series and supplementing the established RE 4-1 as part of its two-product line strategy. With the price-performance ratio, the machine fulfils the requirements of the volume business in particular.

A 170″ version of the machine has already been on sale in China for several months. The pre-release got off to a successful start. Encouraged by the feedback from the market, KARL MAYER has developed an RE 4-1 with a working width of 190″ and will be offering both models to its global customers from middle of July 2024.

The RE 4-1 can be ordered with E 28 and E 32 gauges. The 170" version is also available with E 36. The standard equipment includes KAMCOS® 2, batching device 18 E, Carbon fibre technology and N-pattern drive for controlling the guide bars: stitch-forming GB 1 to GB 3 and inlayGB 4. There are also optional features, including sensors for measuring the yarn tension, laser stop, batching device 34 A, LED lighting and an installation kit.

With its technical configuration, the RE4-1 is optimised for the production of elastic and non-elastic standard fabrics, especially for the underwear sector. One of the top products of the Raschel machine with its high productivity and short amortisation time is elastic Power net. This open-meshed, airy fabric has become an indispensable part of the lingerie and clothing sector. It is often used in the wings of bras as well as for inserts in sports leggings, shirts, jackets and swimwear, where it provides delicate control and comfort. Power net can also be found in semi-technical applications, for example as outer and inner pockets for rucksacks and clothing.

In addition to Power net, Raschel Locknit, Sleek net and Satin net are also part of the production repertoire of RE 4-1. The fabrics with a decreasing density from Raschel Locknit to Satin net also play a role in underwear and clothing production. For their production, filament yarn is threaded in the front two guide bars and elastane in the back ones.

KARL MAYER Verwaltungsgesellschaft AG