Neonyt-Konferenz Fashionsustain beleuchtete den Status Quo der Textil- und Modebranche

Von A wie „Avatar“ bis Z wie „Zero Impact“ – während der Neonyt-Konferenz Fashionsustain wurden vom 6. bis 8. Juli 2021 der Status Quo der Textil- und Modebranche beleuchtet, Innovationstreiber identifiziert und Handlungsspielräume für den Retail-Sektor definiert. Die multidisziplinäre Konferenz streamte mehr als 20 Stunden Impuls-Insights, Panel Discussions und Fashion Deep-Dives live aus dem FFW Studio. Mit dabei waren unter anderem der Grüne Knopf, Oeko-Tex, PwC und die Transformers Foundation.

Die digitale Transformation beschleunigt sich in der gesamten Textil- und Modebranche in einem noch nie dagewesenen Tempo. Dies erfordert, dass alle Akteur*innen ihre Denkweise auf Agilität umstellen, um in disruptiven Umgebungen skalieren zu können. Es muss ganzheitlich gedacht werden – in Bezug auf Produktionsstandards, aber auch wenn es um die Inklusion unterschiedlichster Zielgruppen geht. Mode ist Selbstdarstellung, Identität, es geht um politische Statements und sie spiegelt gesellschaftliche Themen wider.

State of the Industry

Das Framework für die Fashionsustain wurde am ersten Konferenztag gelegt: Als einen Ausgangspunkt für die Diskussion über die Auswirkungen der Covid-19-Pandemie auf die Textil- und Modeproduktion sieht Mariska Schennink, Manager Sustainability von Euretco Fashion, die vorherrschende Schieflage in der Industrie. Um diese deutlich zu machen, ist es für Andreas Bothe, Head of CSR & Sustainability der Bay City Textilhandels GmbH, unausweichlich für Transparenz entlang der Lieferkette zu sorgen.*

Innovating the Industry

Digitalisierung hängt unmittelbar mit Datenmengen zusammen – Big Data, die dabei helfen kann, Konsument*innen oder Brands zu verstehen und die Customer Journey zu optimieren.

Eine Technologielandschaft, die Sam Fields, Director of Creative Technology bei RYOT International, zu Beginn der Covid-19-Pandemie nicht gesehen hat: „Die Modeindustrie befand sich in einer Krise und sie war nicht wirklich vorbereitet auf ein vollständig immersives, digitales Zeitalter. Digital Fashion künftig so einzubinden, dass dabei Technologien wie XR und Blockchain zunutze gemacht werden, wird die Branche revolutionieren und für eine grünere, nachhaltigere Zukunft sowie steigende, hochprofitable neue Einnahmenquellen sorgen.“*

State of Retail

Die Einzelhandelsbranche hat einen enormen Wandel durchlaufen, insbesondere während der Covid-19-Pandemie – die digitalen Angebote verändern die Branche und sie muss sich schnell an neue Kund*innenbedürfnisse anpassen. Die Frage ist nicht mehr physisch oder digital: Phygital ist die Lösung.*

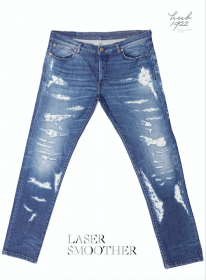

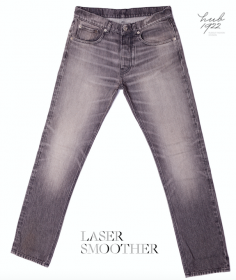

Special Cotton and Denim

Transparente und differenzierte Informationen sind auch ein zentrales Thema beim Thema Baumwolle, dem wichtigsten Rohstoff der Denim-Industrie. “Rund 30 Millionen Menschen weltweit bestreiten ihr gesamtes Jahreseinkommen in der Baumwollindustrie”, so Dr. Kreshav Kranthi, Lead Scientist des International Cotton Advisory Committee. Um deren Anbau ranken sich viele Mythen: „Was den Anbau angeht, hat Baumwolle einen schlechten Ruf”, sagt Wil Jackman, Agronomy Assistant auf der Baumwollfarm Sundown (Australien). Gemeinsam mit dem Baumwollfachmann Simon Ferrigno untersucht die Transformers Foundation in einer Studie deshalb aktuell Aussagen wie z.B. “20.000 Liter Wasser werden für ein T-Shirt oder eine Jeans benötigt”.

*Weitere Informationen finden Sie im Anhang.

Neonyt FASHIONSUSTAIN Sustainability digital Lieferkette Textile Lieferkette Einzelhandel cotton Denim

Neonyt / Messe Frankfurt GmbH