HEREWEAR is winner of the Cellulose Fibre Innovation of the Year

At the "International Conference on Cellulose Fibers 2024" in Cologne, Germany, the Nova Institute for Ecology and Innovation awarded first place in the Innovation Prize to the project partners of the EU-funded HEREWEAR project. They presented a dress made of cellulose fibers, which is entirely made of straw pulp.

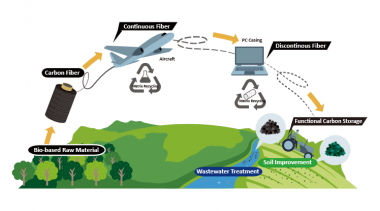

HEREWEAR is an EU-wide research project that brings together partners from research and industry. They are working to establish a European circular economy for locally produced textiles and clothing made from bio-based raw materials.

The HEREWEAR consortium consists of small and medium-sized enterprises and research institutions. HEREWEAR covers all the necessary expertise and infrastructure from academic and applied research and industry from nine EU countries.

The HEREWEAR approach includes technical and ecological innovations in the production of fibers, yarns, fabrics, knitwear and garments, as well as the use of regional value chains and the circular development of fashion items.

New technologies for wet and melt spinning of cellulose and bio-based polyesters, e.g. PLA, from which yarns and fabrics are produced, form the technical basis. Coating and dyeing processes have been developed and tested as part of the project. In addition to reducing the carbon footprint of the product, another environmental goal is to reduce the release of microfibers throughout the textile manufacturing process and life cycle.

Improving the sustainability and recyclability of the developed garments is ensured by design for circularity and digitally networked production means. On-demand production is realized in so-called "microfactories", which are individualized and produce only for actual demand. This production method can be achieved through regional, networked value chains and enables the traceability of materials and manufacturing processes.

The dress presented at the award ceremony is an example of the cooperation and the different qualifications of the project partners: TNO (Netherlands Organization for Applied Scientific Research) provided sustainably produced pulp. The HighPerCell fibers were produced in DITF's spinning facilities. At the same time, designers from the fashion label Vretena created the design for the flexible, two-piece dress, which can be knitted without cutting waste. DITF textile experts worked with the designers to develop the knitting pattern. DITF textile engineers and technicians produced the knitted fabric and assembled the dress at the institutes’ technical center. DITF computer scientists and engineers created the "value chain" and "digital twins" for digital traceability of the production processes.

The innovation prize was awarded to the HEREWEAR consortiu for their joint achievement. Representatives of DITF Denkendorf and Vretena accepted the award on behalf of the EU project partners.

Deutsche Institute für Textil- und Faserforschung (DITF)