Intertextile Shanghai Home Textiles – Autumn Edition 2025 opens next week

Intertextile Shanghai Home Textiles – Autumn Edition is set to return from 20 – 22 August 2025 at the National Exhibition and Convention Center (Shanghai), once again positioning itself as Asia’s preeminent platform for the global home and contract textile industry. With nearly 900 exhibitors representing 20 countries and regions, including eight new countries, the event will span 100,000 sqm across four halls, showcasing the latest cutting-edge products, market trends, and design concepts. The fair will offer a comprehensive fringe programme that aims to inspire, inform, and connect industry professionals. Focusing on sustainability and innovation that will shape the future of home textiles, the 2025 edition promises a vibrant exchange of ideas and opportunities to forge meaningful business partnerships in an increasingly competitive landscape.

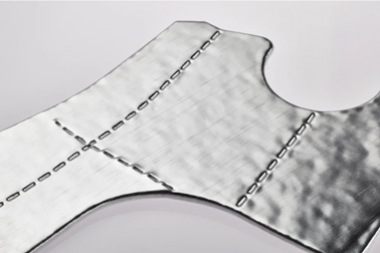

To enhance sourcing efficiency and cultivate meaningful business connections, the fair will present 15+ dedicated product zones encompassing upholstery and sofa fabrics, bedding, curtains, sun protection, and more. These zones will be organised across four halls – 5.1, 5.2, 6.1, and 6.2 – with each hall spotlighting a particular category: Brand Fabrics Hall (5.1), Trendy Fabrics Hall (5.2), International Brands & Household Hall (6.1), and Furniture Fabrics Hall (6.2). Additionally, visitors will benefit from contract business services offered by exhibitors, providing access to specialised expertise and tailored solutions that can enhance their sourcing and operational efficiency.

The Editors Zone is a prominent area featuring a curated lineup of design-focused exhibitors presenting both domestic and international brands. 20 exhibitors will represent 53 high-end brands from 16 countries and regions – 23 of which are new. These brands primarily originate from Western Europe, the US, South Asia, and East Asia. Among the new exhibitors in the Editors Zone are Art Home Korea (Korea) (5.1H C18), Kaeen Sdn Bhd (Malaysia) (5.1H C08), and more. Notable names such as Beijing Ya Da (China), Rioma (Spain), and Raffinato (USA) will be present.

Home textile industry represented by global players

This year, the fair will welcome international exhibitors from 20 countries and regions, including Australia, Belgium, China, Germany, Hong Kong, Iran, Japan, Korea, Portugal, Spain, Türkiye, the UK, and the US. Notably, eight new countries – Bulgaria, Egypt, Finland, Indonesia, Malaysia, the Netherlands, and Vietnam – are joining this diverse lineup.

On the domestic front, six major Chinese home textile pavilions – representing Haining, Huzhou, Linping Hangzhou, Shaoxing, Wujiang Suzhou, and Tongxiang – will showcase regional strengths and innovations.

To date, buyers from 63 countries and regions have pre-registered, with 19 buyer delegations (up 73% from the 2024 edition) confirmed from 23 countries including China, Japan, Malaysia, Myanmar, Thailand, Vietnam, Central Asia, Uganda, Ethiopia, Chile, Colombia, Mexico, El Salvador and more.

Fringe programme: four new themes guiding the future of home textiles

Collectively emphasising the dynamic nature of the home textiles industry – NextGen, Palette, Connector and Go-Green – will focus on creativity and aesthetics in design, fostering collaboration through shared business strategies and market insights, showcasing innovations and advancements in textiles, and addressing sustainability trends and technological needs to align with market demands. Key highlights include:

- Future & Textile Zone (NextGen): where participants can discover future-focused materials, and AI trends lead by Ms Anja Bisgaard Gaede, CEO of SPOTT trends & business.

- Designer Tour and Guided Tour (Palette): Ms Camilla Rudnicki (Founder of Camilla Rudnicki Home & Interior, Denmark), offering curated walkthroughs of standout exhibits with visitor.

- Econogy [1] Forum (Go-Green): will address the dual challenges of sustainability and technological advancement. Leading experts from China, Hong Kong, Italy, and the US will share cross-disciplinary insights and case studies, focusing on how integrated advancements in technology, design, and business models can support a more sustainable textile industry.

Additional highlights include The Home Textiles x Interior Decoration Summit (Connector), will gather thought leaders to explore the transformation of the industry and its future direction. A series of market strategy seminars will provide valuable insights into regional developments, with featured sessions from Colombia, Uzbekistan, and Vietnam.

Furthermore, the 2026 / 27 China Home Textile Trend Area (Palette) will offer an exclusive preview of upcoming domestic design and consumer trends. Rednote: Weaving the Ideal Home, Home Textile Trend Insights (Connector), and From Cross-Boundary to Boundless: The 11th Home Furniture & Textile TOP Business Matching (Connector) will also be taking place.

Intertextile Shanghai Home Textiles – Autumn Edition is organised by Messe Frankfurt (HK) Ltd; the Sub-Council of Textile Industry, CCPIT; and the China Home Textile Association (CHTA).

Messe Frankfurt HK, Ltd