ANDRITZ at ANEX/SINCE 2021

International technology Group ANDRITZ will be presenting its innovative nonwovens production and textile solutions at ANEX/SINCE 2021 in Shanghai, China, from July 22 to 24, 2021. The product portfolio covers state-of-the-art nonwovens and textile production technologies such as air-through bonding, needlepunch, spunlace, spunbond, wetlaid/Wetlace, converting, textile finishing, airlay, recycling, and bast fiber processing.

Among the largest end-use markets for nonwoven products are materials for durable uses. Interior linings for cars, materials for construction, geotextiles, synthetic leathers for clothing and furniture, carpeting, filtration and many other industries rely on the use of nonwovens produced using the needlepunch method.

ANDRITZ Nonwoven’s processes play a pioneering role in the production of biodegradable materials. For many years, ANDRITZ has offered different processes, like spunlace, Wetlace and Wetlace CP, all with one goal in mind: Elimination of plastic components while maintaining the high quality of the desired product properties. Such processes achieve high performance entirely with plastic-free raw materials. The added benefit of using a blend of fibers, like wood pulp, short-cut cellulosic fibers, viscose, cotton, hemp, bamboo or linen, without chemical additives results in a 100% sustainable fabric, thus meeting customers’ needs exactly as well as supporting the strong tendency to move away from plastics and synthetics.

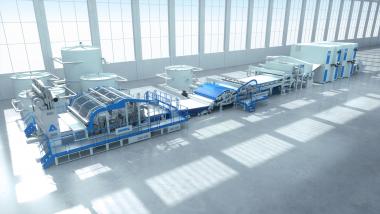

The latest development in this field is the ANDRITZ neXline wetlace CP line. This process combines the benefits of two forming technologies (inline drylaid and wetlaid web forming process) with bonding by hydroentanglement. Natural fibers, like pulp or viscose, can be processed smoothly and generate a high-performance and cost-efficient wipe that is fully biodegradable and plastic-free.

Andritz