Reifenhäuser Enka Tecnica exhibits high-end components at INDEX

Reifenhäuser Enka Tecnica will exhibit its wide range of replacement components for spunbond, meltblown, and composite lines at the world's leading nonwovens trade show INDEX in Geneva from October 19 to 22, 2021. The highly specialized custom manufacturer offers high-end technology "Made in Germany" that is 100% compatible with all globally installed lines.

Producers of nonwovens worldwide rely on Enka Tecnica components to manufacture products for complex applications in hygiene, medical or filtration to provide them with access to new profitable markets. Trade-show visitors will gain a detailed insight into the entire range of products, from meltblown and spunbond spinnerets to meltblown cassettes and complete meltblown spinning beams designed with an energy concept optimized for sustainability. The tips and capillaries assure consistent product quality and precision, allowing producers to meet their tolerance specifications reliably and avoid scrap at the same time..

With its refresh service for refurbishing used components, Enka Tecnica not only offers a cost-efficient alternative to new parts, but also extremely fast delivery times, a factor that is often decisive to maintain daily production targets. Visitors to Geneva will be able to see the quality of refresh components displayed at the booth - a meltblown and a spunbond spinneret, half of which has been refurbished. They will be able to see the condition of the capillary holes before and after the refresh through a microscope.

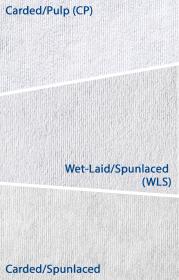

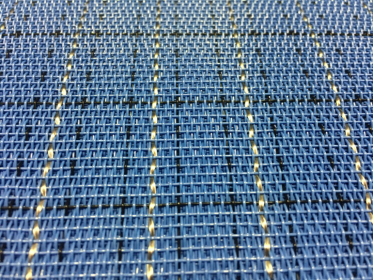

Another trade show highlight includes jet strips for hydroentangling nonwovens. Depending on the application, they are offered in Smart, Advanced, and Premium versions and have a special unique selling point – the strips are fully hardened, whereas competitor products usually only have a hardened surface. This quality advantage results in significantly longer service lives, which is why they are also known on the market as "The World's Hardest Strips”.

Reifenhäuser Reifenhäuser Enka Tecnica INDEX nonwovens spunbond technology meltblown technology

Reifenhäuser GmbH & Co. KG Maschinenfabrik