HeiQ/Nylstar: Launch of HeiQ Viroblock Permanent on Meryl® Skinlife Force

A decade long collaboration between Swiss textile innovator HeiQ and Spanish premium synthetic fiber manufacturer Nylstar, has resulted in the innovation of a revolutionary new premium antiviral and antimicrobial textile with zero pollution sustainable benefits, Meryl® Skinlife Force powered by HeiQ Viroblock Permanent, winner of ISPO Textrends Award for the Best Product.

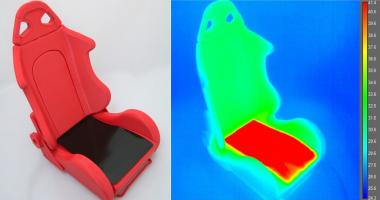

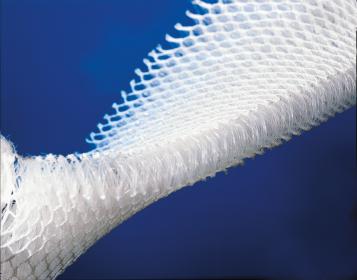

The new technology is used exclusively on Meryl® Skinlife Force, an hi-tech fabric that combines the silver-ion active principle antimicrobial properties developed by HeiQ and Nylstar’s hydrogen-based technology which allows the creation of yarns with a very strong molecular cohesion structure. The Hydrogen molecular structure makes Meryl® Skinlife Force a high-performance fabric in terms of moisture management and breathability, offering a natural stretch without elastane as well as excellent durability thanks to its continuous and high tenacity filaments. The robust durability of HeiQ Viroblock Permanent is achieved thanks to the silver particles being added directly into the raw polymer of the yarn thereby keeping these properties active for the lifetime of garments. Fabric samples successfully demonstrated a very strong antimicrobial efficacy with over 99.99% reduction of both gram-positive and gram-negative bacteria after 100 washes. Antiviral test is underway.

Both HeiQ and Nylstar will be “exhibiting” at ISPO Munich Online from February 1st to 5th. Nylstar won the Textrends 2021 Award for the Best Product in the Base Layer Category.

HeiQ Nylstar synthetic fibers and yarns antiviral antimicrobial Sustainability ISPO Munich

HeiQ Materials AG