SHIMA SEIKI to exhibit at Techtextil 2022 in Frankfurt

SHIMA SEIKI MFG., LTD. of Wakayama, Japan, along with its Italian subsidiary SHIMA SEIKI ITALIA S.p.A., will be participating in the Techtextil exhibition in Frankfurt, Germany from the 21st till the 24th of June 2022.

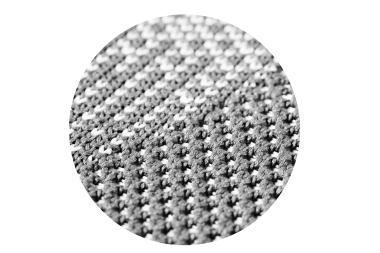

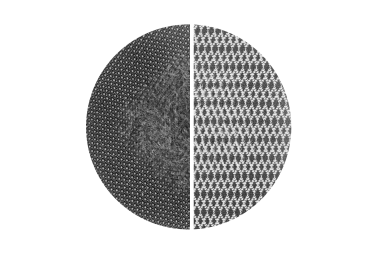

On display will be SHIMA SEIKI’s latest innovation in flat knitting technology as applied to the field of technical textiles—a prototype weft knitting machine capable of multi-axial yarn insertion. Fabrics produced on this machine use inlay technique for the production of hybrid textiles that combine the stretch characteristics of knitted fabrics with the stability of woven textiles, suited to various technical applications. To this, warp yarn is inserted to further expand its capability to produce 3D-shaped carbon fiber and composite preforms directly on the machine. This is made possible by taking advantage of the fact that flat knitting as a textile production method is capable of producing end products that are shaped-to-form and with added thickness. Compared to current methods of preform production, savings in post-processing time, material, labor and associated costs are immense, realizing efficient and sustainable production. SHIMA SEIKI’s own yarn unwinding technology is also used for optimum yarn feed and tension for use with technical yarns that are otherwise difficult to knit. Industrial textile samples knit on the multi-axial machine will also be available for examination on-site.

SHIMA SEIKI's SDS®-ONE APEX4 3D design system will be available for demonstrations as well. Of particular interest should be its ultra-realistic simulation capability that realizes Virtual Sampling. When countless variations must be evaluated before arriving at a final design, virtual product samples can be used to streamline the decision-making process by minimizing the enormous amount of time, cost and material normally associated with producing actual samples for each variation. When approved, the same data can be converted to machine data for immediate knitting, significantly reducing lead times.

Shima Seiki flat knitting Technical Textiles Techtextil Messe Frankfurt Exhibition GmbH

SHIMA SEIKI MFG., LTD.