Texhibition Istanbul: Fifth edition successfully concluded

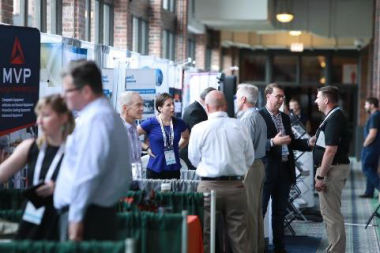

The fifth edition of the Texhibition Istanbul Fabric and Textile Accessories Fair from 6 to 8 March 2024, organised by İTKİB Fuarcılık A.Ş. in cooperation with the Istanbul Textile Exporters Association (İTHİB), presented 557 exhibitors showcasing the entire range of the textile supplying section: from woven and knitted fabrics to accessories and artificial leather. A new addition was a separate hall for yarns and denim, the BlueBlackDenim hall. With this trade fair, Texhibition has more than doubled its floor space compared to the last event to 35,000 square metres.

Exhibitors

Texhibition Istanbul acts as a central point of contact for the entire international industry, with a clear focus on quality, innovation and the latest trends like the denim companies Bossa, Çalık, İsko, İskur and Kipaş at the BlueBlackDenim Hall.

Yarn companies such as Aksa, Diktaş, Ensar, Karafiber, Kaplanlar, Korteks, Migiteks, Sasa, Tepar showed the production power of the yarn sector, where the product quality, design and workmanship came together.

In addition to well-known companies such as Almodo, Bahariye, BTD, Can Textile, Iskur, Kipaş, Menderes, Söktaş, Yünsa, Zorlu, İpeker a large number of other export-oriented companies from the segments of textiles (woven fabrics, knitting) presented their latest designs and products.

Visitors

25,752 visitors came from over 112 countries, 41.8% from the European Union (including Germany, Italy, the Netherlands, Spain, Romania etc.) and Great Britain, Ukraine,26.5% from Asia (including Russia etc.), 14.8% from the Middle East (including Jordan, United Arab Emirates, Saudi Arabia) 10.7% from North Africa (including Algeria, Tunisia etc.), 3.1% from North America (United States, Canada), 3.1% from South America and other countries.

American buyers from the USA and Canada in particular, but also a large number of Mexican and Colombian buyers took advantage of the numerous match-making opportunities at Texhibition. Many B2B meetings took place and led to numerous orders being placed, including from key accounts such as Alexander Wang, Asos, Forever 21, Sainsbury's, Veronica Beard etc.

JANDALI