Devan/Jeanologia: Reduced water usage for post garment treatments

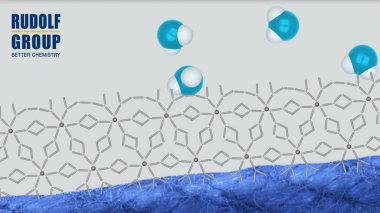

Devan, one of the leading companies in sustainable and functional textile finishes, has been working together with Jeanologia, a global leader in sustainable and efficient finishing technologies for textiles, to reduce further water consumption during the application of Devan’s awarded BI-OME® antimicrobial and R-Vital® skincare range.

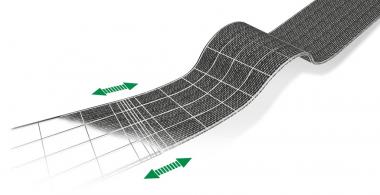

With increased attention to climate change and limiting excess water consumption in textile production (whether denim or other textiles), Devan and Jeanologia worked together to evaluate the application of Devan finishes onto garments via the patented e-Flow technology.

e-Flow technology can accomplish a considerable number of finishing effects with the highest quality, a minimal amount of water and zero discharge. The technology uses micronization and nebulization to substitute traditional abrasion process and deliver performance chemistry using nano-bubbles instead of water. It reduces the cost of application, saves the amount of water used and ensures that the correct amount of chemistry stays in the garment and not in the water. e-Flow is the perfect fit for every industrial washing machine. This allows mills and brands to apply Devan’s technologies in a more sustainable way than using traditional application equipment, even for smaller production runs and direct onto garments.

“With the global textile production using 4% of the global freshwater withdrawal, here at Devan we are continuously working on more sustainable solutions”, says Dr. Vanessa Daelman, CTO at Devan. “Next to this, we of course highly value sustainable application methods from Jeanologia, like e-Flow, in order to reduce the excess water usage during textile application. We are delighted that we could work together with Jeanologia and establish that Devan technologies can be easily applied via these technologies onto garments or fabrics like denim and with full retention of functionality. This application method also allows post garment treatment of our finishes, for example an antimicrobial treatment onto already finished garments, which will be increasingly important in a more circular textile world where re-use plays an important role”, Dr. Daelman concludes.

Marketing Solutions NV