DITF: Recyclable event and trade fair furniture made of paper

A lot of waste is generated in the trade fair and event industry. It makes sense to have furniture that can quickly be dismantled and stored to save space - or simply disposed of and recycled. Paper is the ideal raw material here: locally available and renewable. It also has an established recycling process. The German Institutes of Textile and Fiber Research (DITF) and their project partners have jointly developed a recycling-friendly modular system for trade fair furniture. The "PapierEvents" project was funded by the German Federal Environmental Foundation (DBU).

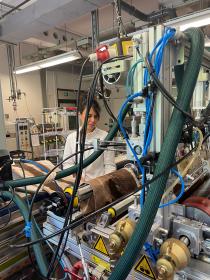

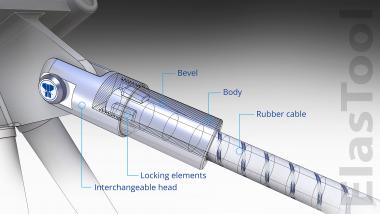

Once the paper has been brought into yarn form, it can be processed into a wide variety of basic elements using the structure winding process, creating a completely new design language.

The unusual look is created in the structure winding process. In this technology developed at the DITF, the yarn is deposited precisely on a rotating mandrel. This enables high process speeds and a high degree of automation. After the winding process, the individual yarns are fixed, creating a self-supporting component. A starch-based adhesive, which is also made from renewable and degradable raw materials, was used in the project for the fixation.

The recyclability of all the basic elements developed in the project was investigated and confirmed. For this purpose the research colleagues at the project partner from the Department of Paper Production and Mechanical Process Engineering at TU Darmstadt (PMV) used the CEPI method, a new standard test procedure from the Confederation of European Paper Industries.

Sensor and lighting functions were also implemented in a recycling-friendly manner. The paper sensor yarns are integrated into the components and detect contact.

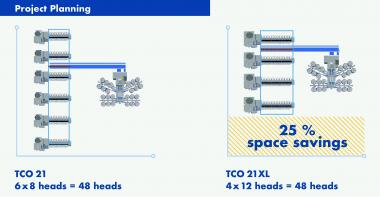

Also, a modular system for trade fair and event furniture was developed. The furniture is lightweight and modular. For example, the total weight of the counter shown is well under ten kilograms and individual parts can easily be shipped in standard packages. All parts can be used several times, making them suitable for campaigns lasting several weeks.

A counter, a customer stopper in DIN A1 format and a pyramid-shaped stand were used as demonstrators. The research work of the DITF (textile technology) and PMV (paper processing) was supplemented by other partners: GarnTec GmbH developed the paper yarns used, the industrial designers from quintessence design provided important suggestions for the visual and functional design of the elements and connectors and the event agency Rödig GmbH evaluated the ideas and concepts in terms of usability in practical use.

DITF German Institutes of Textile and Fiber Research Denkendorf recycled paper paper yarn Recycling trade fairs

Deutsche Institute für Textil- und Faserforschung (DITF)