Completion of Mosque for workers of Fashion Forum Limited

The Zebun Nessa Mosque, recently completed in Ashulia, Dhaka, is a shining example of the progressive initiatives being undertaken by the Bangladeshi garment industry. Fashion Forum Ltd., a company of IDS Group, spearheaded this project, demonstrating a strong commitment to enhancing the welfare and environment for its workers.

Bangladesh, renowned as the second-largest exporter of ready-made garments globally, is setting new benchmarks in workplace safety, worker welfare, and environmental sustainability. Mr. Idris Shakur, managing director of IDS Group, epitomizes the industry’s progressive outlook. He has dedicated the mosque to the workers of Fashion Forum Limited, naming it in honour of his late mother. The gesture is designed to foster compassion and unity within the industrial community.

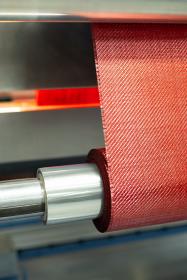

The mosque, designed by Studio Morphogenesis and completed in 2023, reflects a forward-thinking architectural philosophy. Sustainability was a core consideration, with the design incorporating recycled red bricks from demolished houses for the exterior walls. Pink concrete, weatherproofed with lime plaster mixed with red brick powder, blends tradition with modernity, creating a spiritual and communal haven for the workers.

A key feature of the mosque is its majestic arched opening facing the qibla, offering worshippers a serene view of the adjacent waterbody and enhancing their connection with nature. The structure's double-layered walls provide thermal comfort and facilitate natural light and ventilation, transforming the mosque into a "breathing pavilion." Enclosed gardens, reminiscent of light courts, provide a peaceful retreat from the bustling industrial environment.

Inside, an intricate perforated metal stairway leads to a crescent-shaped upper floor, dedicated exclusively to the female workers. This space serves as a serene meeting area and prayer room, empowering women and reinforcing their importance within the workforce.

The Zebun Nessa Mosque also showcases advanced construction technology, designed to withstand extreme weather conditions, further underscoring the innovative and resilient spirit of Bangladeshi garment manufacturers.

This mosque stands as a testament to the progressive and compassionate ethos driving Bangladesh’s garment industry. It highlights how manufacturers are not only focusing on economic growth but also prioritising the well-being and empowerment of workers, setting new standards for the industry worldwide.

Bangladesh Apparel Exchange