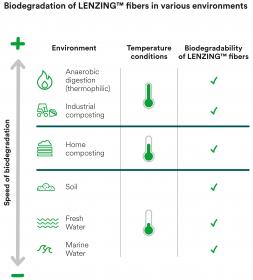

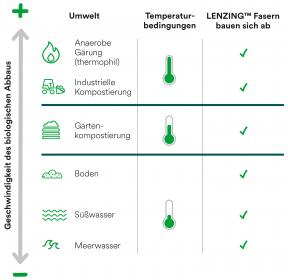

LENZING™ fibers are fully biodegradable in water, soil and compost

- Organic Waste Systems and TÜV confirm fiber biodegradability also in fresh water

- All white LENZING™ Viscose, Modal and Lyocell fibers are now certified for all environments

- Global legislators aim at limiting plastic waste persisting in the environment for centuries

- EU Single-Use Plastics Directive partly regulates usage of plastic products

- Biodegradable materials such as wood-based fibers are the best alternative to single-use plastics

The Lenzing Group received confirmation of the full biodegradability of its fibers in fresh water by the independent research laboratory Organic Waste Systems (OWS). The new and existing international certifications conducted by OWS and issued by TÜV Austria verify that LENZING™ Viscose fibers, LENZING™ Modal fibers and LENZING™ Lyocell fibers are biodegradable in all natural and industrial environments: in the soil, compost as well as in fresh and in marine water.

The biodegradability of cellulosic products and the synthetic fiber polyester was tested in fresh water at OWS according to valid international standards, e.g. ISO 14851. At the end of the trial period, LENZING™ wood-based cellulosic fibers, cotton and paper pulp were shown to be fully biodegradable in fresh water in contrast to synthetic polyester fibers. The fact that synthetic materials are not biodegradable leads to major problems in wastewater treatment plants and potentially marine litter. In turn, this not only harms fish and birds living in and close to the oceans but also all marine organisms and us humans.

“The Lenzing Group operates a truly circular business model based on the renewable raw material wood to produce biodegradable fibers returning to nature after use. This complete cycle comprises the starting point of the core value of sustainability embedded in our company strategy sCore TEN and is the ‘raison d’etre’ of our company”, says Stefan Doboczky, Chief Executive Officer of the Lenzing Group. “In living up to this positioning, we not only enhance the business of our suppliers, customers and partners along the value chain but also improve the state of the entire textile and nonwovens industries.”

Both the textile and nonwovens industries face huge challenges with respect to littering. If current trends continue, the oceans could contain more plastic than fish by 2050. Therefore, legislative bodies worldwide can no longer ignore the issue and have moved towards plastics legislation aimed at limiting the vast amount of waste. In response, European lawmakers issued the Single-Use Plastics Directive currently being transposed into national legislation in the EU member states.

Conventional wet wipes and hygiene products mostly contain plastic and were thus identified as one of the product categories to be singled out. Less polluting alternatives are generally encouraged by NGOs and legislators, e.g. products made of biodegradable wood-based cellulosic fibers. Plastic waste including microplastic can persist in the environment for centuries. In contrast, biodegradable materials are the best alternative to single-use plastics because they fully convert back to nature by definition and thus do not require recycling.

Corporate Communications & Investor Relations

Lenzing Aktiengesellschaft