New JEC Group Publication

- COMPOSITES SUSTAINABILITY REPORT 2021

JEC Group in collaboration with EuCIA has published the first edition of the Composites Sustainability report 2021. This report seeks to give highlights about the part composite materials are playing in creating the sustainable European economy of the future.

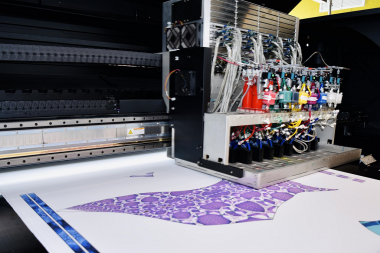

The contents of the book are comprehensive: starting with discussions around the widely recognised Life Cycle Assessment methodology for calculating the environmental impact of products, it then

moves through a series of analyses and case studies presenting the Circular Economy approach and ranging from raw materials (including bio-based) to industrial components.

The purpose of the work, rather than results, which quickly become obsolete, is to give examples of approaches contributing to and moving towards sustainability. To do so, JEC Group has arbitrarily split

the value chain into five parts:

• Background, LCA, circular economy ;

• Concept, design, raw materials ;

• Production, processes, waste ;

• Recycling, recovery ;

• Applications.

The book “Composites sustainability Report 2021” is for sale online.

JEC Group European Composites Industry Association EuCIA Composites Sustainability

JEC Group