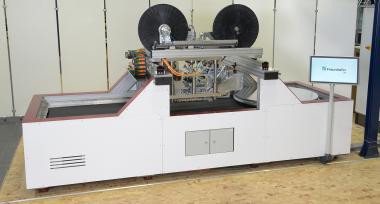

Oerlikon Nonwoven showcases convincing meltblown and spunbond technology

The Oerlikon Nonwoven experts will be presenting efficient solutions and comprehensive technology know-how for challenging filtration tasks to an international trade audience at the FiltXPO 2020 in Chicago, USA (Stand # 420), taking place between February 26 and 28.

Meltblown technology is one of the most efficient methods for producing very fine and highly-separating filter media made from manmade fibers. New, unique and highly-sophisticated filter media are easy to manufacture thanks to Oerlikon Nonwoven’s optimized meltblown technology. This process is characterized by its constant melt pressure distribution and consistent dwell time across the entire width of the spinning beam, Furthermore, the novel guidance and distribution of the process air outside the coathanger distributor offered by the Oerlikon Nonwoven technology prevents so-called hotspots, which overall ensures particularly homogeneous nonwoven properties and basis weights even in the case of delicate raw materials.

The Oerlikon Nonwoven charging unit stands out against other concepts currently available on the market. Users can freely choose from a large number of variation possibilities and set the optimum charging method depending on the filter application, allowing the Oerlikon Nonwoven charging unit to also be used for the manufacture of EPA- and HEPA-class filter media.

The new forming section ensures improved nonwoven formation evenness across the entire width, even in the case of high spinning speeds, special polymers and polymer combinations. In addition to this, the newly-designed system also ensures that nonwovens only require minimal edge trimming at the end of the production process. The newly-developed mixedfiber technology enables the combining of various filament cross-sections and polymers, in order to set ideal filtering and pleating performances, for example.

Oerlikon Nonwoven