SHIMA SEIKI to exhibit at Pitti Filati

SHIMA SEIKI ITALIA S.p.A., Italian subsidiary of leading Japanese computerized knitting solutions provider SHIMA SEIKI MFG., LTD., will exhibit at the 93rd edition of the Pitti Immagine Filati exhibition in Florence, Italy. It will exhibit as part of the new CustomEasy section, which explores the various aspects of customization in the presence of textile machinery, including a multi-faceted lineup of SHIMA SEIKI WHOLEGARMENT® knitting machines.

The WHOLEGARMENT® knitting machine SWG-XR® features 4 needle beds for all-needle knitting of high quality WHOLEGARMENT® products using the company's original SlideNeedle™. SWG-XR® features a re-designed sinker system and a compact, light-weight carriage featuring 4 systems as well as auto yarn carriers. All contribute to increased productivity of more than 25% over the previous MACH2®XS machine, as well as increased product range using a wider variety of yarn for supporting knits for all seasons, and higher quality for knitting beautiful fabrics and silhouettes; even items that were impossible to knit with the MACH2® series, including punch-lace patterns, variable stitch knitting and intarsia knitting. Setting new standards for the next generation of waste-free, sustainable WHOLEGARMENT® knitting, SWG-XR® at Pitti Filati will be shown in 18L.

Affectionately referred to as “SWG®-Mini,” SHIMA SEIKI's compact line of WHOLEGARMENT® machines allows customers to take advantage of the same short lead times and versatile production as larger WHOLEGARMENT® knitting machines, but with minimal investment. SWG®091N2 with its 36-inch (90cm) knitting width is especially suited to knitting a wide variety of items including accessory items as well as childrenswear and smaller size garments, all without the need for linking or sewing afterward. At Pitti Filati SWG®091N2 will be shown in 5 gauge.

A new proposal in WHOLEGARMENT® knitting will also be shown in the form of the N.SVR®183 WHOLEGARMENT® knitting machine. SHIMA SEIKI's global standard in shaped knitting, the N.SVR® series now features a model for producing WHOLEGARMENT® knitwear using every other needle in fine gauge. N.SVR®183 is equipped with the R2CARRIAGE® system and a compact, lightweight carriage for even higher productivity. Shown in 21G at Pitti Filati 93, N.SVR®183 is the ideal machine for flexible, entry-level WHOLEGARMENT® production, with the versatility to respond to fluctuating market demand.

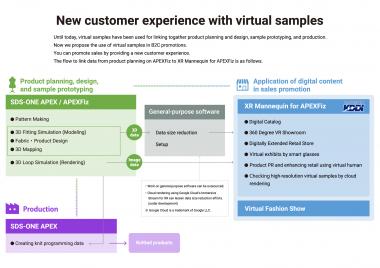

APEXFiz® subscription-based design software supports the creative side of fashion from planning and design to colorway evaluation, realistic fabric simulation and 3D virtual sampling. Virtual samples are a digitized version of sample making that are accurate enough to be used effectively as prototypes. By replacing physical samples, virtual samples reduce time, cost and material that otherwise go to waste. APEXFiz® thereby helps to realize sustainability and digitally transform the fashion supply chain.

Continuing from past editions of Pitti Filati are knit samples produced in collaboration with Italian designer Vittorio Branchizio, as well as samples from SHIMA SEIKI headquarters for assessing the potential of SHIMA SEIKI knitting machines.

SHIMA SEIKI MFG., LTD.