ILUNA Group’s precious sustainable innovation

Able to offer an alchemy of design and sustainable innovation, Iluna Group with ROICA™ by Asahi Kasei join the latest edition of the Milano Unica fair with a range of innovations capable of combining innovation, aesthetics and quality. "Ethical" lace and stockings, where quality standards go hand in hand with fashion content, respecting both the environment and humans, an offer already selected among the protagonists of the Sustainable Thinking Exhibition of the Salvatore Ferragamo Museum, for its value in the field of responsible innovation.

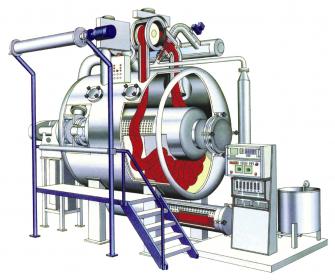

Experts in the production of stretch lace since 1985, ILUNA today represents the largest European laces’producer. Thanks to the effectiveness of their responsible innovation strategy, Iluna Group has been the very first lace producer to have gained the GRS (Global Recycled Standard) for their transformed products, together with the company certification STeP (Sustainable Textile Production by Oeko – Tex®).

GB Network Marketing & Communication