B.I.G. Yarns unveils ColorMind for ultimate design freedom for contract carpets

- Create truly unique yarn designs: with up to 6 colors from a large predefined color range and infinite combinations of twisting & air entanglement

- Endlessly recyclable yarn solution - available in both standard PA6 and 75% recycled content EqoCycle PA6 yarn

- Efficient and flexible - all colors in stock to shorten lead-time; customized lot sizes

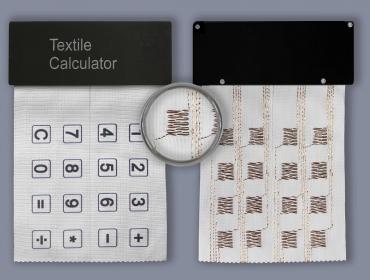

B.I.G. Yarns brings inspirational design freedom to high-end loop-pile contract and automotive carpets with the unveiling of ColorMind. The innovative yarn technology is B.I.G. Yarns’ first venture into a two steps yarn collection, offering a unique solution for creating multi-color PA6 yarns for any carpet design.

Available from mid-June 2021 in both standard and EqoCycle 75% recycled content yarn, designers are invited to work closely with B.I.G. Yarns experts to realize the designs they have always wanted. Combinations of variable levels of twisting and air entanglement, using up to 6 colors at once, elevate design possibilities beyond current limitations.

The ColorMind color bank features predefined colors, always in stock, meaning short lead times. Manufacturers can also benefit from customized lot sizes and bobbin length, creating even more flexibility and design freedom. To preview a taster of the potential directions opened up for loop-pile carpets, B.I.G. Yarns has used the technology to achieve its own “Optica” dot effect and “Illusion” wave effect as inspiration for customers’ design explorations.

“ColorMind offers never-seen yarn diversity to support a new level of design sophistication in high-end carpet segments. We’re very proud and excited to enter into two steps yarns with a solution offering something truly special, the result of intensive dedication from our design and development teams,” comments Emmanuel Colchen, General Manager, B.I.G. Yarns. “ColorMind combines our strengths in delivering high-performance, more sustainable yarns to fit the evolving demands of these segments, underpinned by our expertise in color sequencing and color mixing. We’re looking forward to exciting collaborations and innovative, eye-catching designs for future loop-pile carpets.”

ColorMind PA6 yarns are based on a unique Solution Dyed Nylon yarn and are suitable for Class 33 certification (heavy commercial use). The EqoCycle yarn version is mainly based on post-industrial waste and supports contract and automotive carpet manufacturers with a drop-in circular solution to reduce the ecological footprint of their end carpets.

EMG