Officina+39 presents Better Seasons collection at Munich Fabric Start

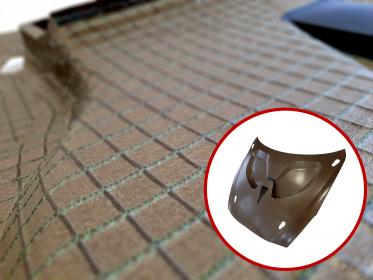

The Italian company Officina+39 will be at Bluezone’s KEYHOUSE area to present its latest sustainable achievements in the field of research and chemical application for the textile sector as well as The Circle Book 2, a special project with circularity as main focus.

For the first time since Covid-19 pandemic hit the world, Munich Fabric Start returns to host some of the most renowned international players in the textile and fashion industry, showcasing their latest innovations. From August 31 to September 1, Officina+39 will step into the Bluezone’s KEYHOUSE area, the interactive hub featuring futuristic solutions with a high level of innovation for the textile supply chain, to present its Better Seasons collection as well as its most recent developments.

The new collection embodies the company’s pillars of Trustainable approach – innovation, sustainable practices, clean information, transparency and social responsibility –, delivering a selection of bold, colorful and conscious solutions for the textile industry. These explore better ways to produce and use less through cuttingedge technologies, specifically developed to reduce the use of energy and hazardous chemicals while increasing waste recycling and water conservation.

Menabò Group srl for Officina+39