The Freudenberg House of Sustainability

- Sustainability concept with more than 500 sustainable and innovative solutions

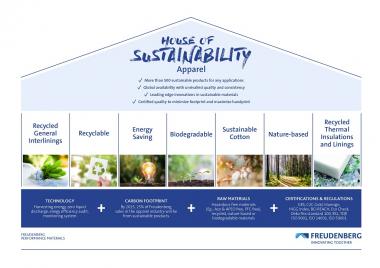

Freudenberg Performance Materials Apparel (Freudenberg) is proud to announce its new House of Sustainability. The initiative is designed to assist customers worldwide in enhancing the sustainability of their products, thereby laying the groundwork for a more sustainable future together with Freudenberg. Customers will find more than 500 sustainable and innovative solutions of premium quality for a comprehensive range of applications in the apparel industry. With this initiative, Freudenberg is making its entire portfolio of sustainable solutions visible and transparent. At the same time, the leading global manufacturer of technical textiles is also driving its roadmap of forward-looking innovations.

Sustainability has been an integral part of business activities ever since Freudenberg was established and the first values and principles were drawn up in 1887. Freudenberg aspires to reduce its own footprint and increase the handprint for customers and end users. This means the company strives to minimize the impact of its production processes on the environment (footprint) while helping customers achieve their sustainability goals by offering appropriate products and services (handprint).

The Freudenberg House of Sustainability

The foundation for the Freudenberg House of Sustainability is made up of four elements: Certifications & Regulations, Raw Materials, Technology and Carbon Footprint. This foundation supports seven pillars providing customers with more than 500 sustainable solutions. The House of Sustainability enables customers to choose the right solutions for their sustainable applications and to meet their sustainability goals efficiently. In addition, all Freudenberg services are visible and transparent.

Launch of the Freudenberg House of Sustainability

The House of Sustainability will be launched worldwide over a 12-week period. Each week, Freudenberg will post in-depth information about the elements and pillars on several channels. The complete House of Sustainability will be presented at ISPO Munich 2022.

Freudenberg Performance Materials House of Sustainability Nachhaltigkeit Sustainability

Freudenberg Performance Materials Holding SE & Co. KG