YKK and GTT Win ISPO Award

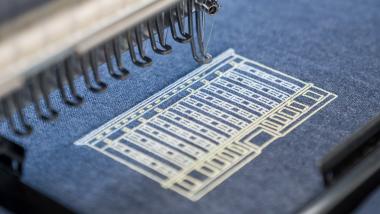

The ISPO Textrends judges have selected YKK's DynaPel™ water-repellent zipper as the Best Product in the accessories category. The competition, held twice a year in conjunction with the ISPO trade show, recognizes the most innovative performance textiles, components, and apparel.

Designed to be compatible with garment recycling systems, the DynaPel™ zipper uses GTT’s EMPEL® technology instead of the standard PU film to achieve its water repellency. The lack of a PU film helps remove one of the barriers of textile-to-textile recycling of performance apparel by eliminating the urethane material, which presents challenges to garment recycling processes.

Conventional chemical and mechanical garment recycling systems cannot process the polyurethane film commonly used on water-repellent zippers, necessitating the removal of zippers from garments before recycling. This additional processing step often deters recyclers from accepting garments with PU zippers, resulting in unnecessary waste.

EMPEL® technology uses advanced green chemistry devoid of PFAS and a specialized manufacturing process that allows the chemistry to penetrate the yarn and encapsulate it with a water-repellent layer through molecular cross-linking. The molecular cross-linking creates an extremely durable layer that is highly resistant to abrasion and invisible to the eye.

Formidable Media / Green Theme Technologies