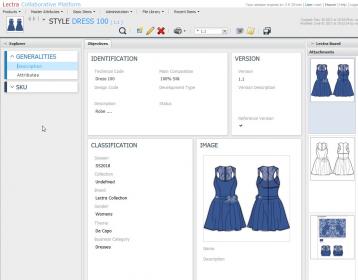

Showcase for the Industry of the Future for Lectra

The Industry of the Future Alliance (AIF) has awarded Lectra with their ‘Showcase for the Industry of the Future’ label for demonstrating the criteria exemplarity, innovation and commitment. This certification is given to companies who have concretely developed a ground-breaking project to organize their production by leveraging the potential of digital.

The AIF bestowed Lectra with this distinction for its competitiveness concerning cost, quality and delivery times, all obtained thanks to a lean approach and reflection around the design of its products. Further, Lectra received the certification for its competitiveness regarding value, achieved thanks to mastering customer use from which new associated services have flowed. Since 2013, Lectra has invested €86 million in R&D, representing 9.4% of its revenues. This Investment has enabled Lectra to undergo a metamorphosis—based on methodological advances and fundamental technologies—increasing recruitment and growing competitiveness in all of its markets and geographical sectors.

With ten years’ experience in the industrial internet of things for cutting and expertise in software Solutions to automate and optimize design and product development, Lectra is in an unrivalled position to Support customers as they enter the ‘industry of the future’ era.

Pressure from certain shareholders to relocate manufacturing to China in 2005, triggered Lectra’s industrial project. Following risk analyses—the cost of transport for the European market, the turnover in qualified labor, uncertainty over patent rights and quality—Lectra decided to keep manufacturing in France. This choice was conditional on: disruptive innovation; upgrading; increased value to customers; and a rise in productivity.

The project was accompanied by a well-structured lean approach and organizational changes, which enabled Lectra to achieve the desired level of excellence in terms of productivity and competitiveness.

Some of the changes that took place thanks to this project are as follows: Growth in industrial performance due to an improvement in working conditions, with teams involved in the lean approach; Production engineers involved in creating awareness around factory constraints for a new offer as early as the design process. This co-design product/process optimizes global costs; Emphasis on product, process and logistics’ modularity with the latest possible integration of options (delayed differentiation). This enables logistics’ constraints to be taken into account as early as the engineering phase. Product modularity allows, for example, machines to be put in containers when they might otherwise require special heavy-goods transport.

Lectra’s factory improved its productivity rate by 18 points in three years, and has since maintained it at 89%. Costs have already reduced by 25% and the quality and level of service has improved. In terms of positioning, Lectra has confirmed its leadership in the high-end segment. Lectra has enriched its offer with end-to-end services and innovative, connected products whose embedded intelligence offers Smart Services, notably for predictive maintenance.

Lectra