COBRA International: Highlights Diversification into New Market Sectors at JEC World 2022

Cobra International, a leading manufacturer of advanced composite products for the watersports, automotive, marine, and industrial sectors, will highlight recent diversification into new composite markets at JEC World 2022, with exhibits ranging from VTOL drones to carbon fibre prosthetics. Cobra will also demonstrate how it is working alongside automotive and water sports customers to further enhance the sustainability of products in these sectors.

High Volume Production Capacity for the UAV sector

Cobra will display a wing from the Swiftlet UAV. This compact tactical fixed wing UAV platform has a 5.5m wingspan and was developed by the Royal Thai Air Force and National Science and Technology Development Agency (NSTDA) for survey, monitoring and search and rescue operations. Cobra manufactured the 32kg Swiftlet composite airframe using a combination of CNC cut carbon sandwich internal structure and PVC foam sandwich skins using both high grade glass fibre and carbon fibre reinforcements.

Sustainability Options for Automotive and Watersports

Sustainability has a been a key focus for the Cobra Waterports division and CAC, the Cobra automotive business unit. At JEC World 2022, Cobra will showcase the increasing material and process options it has developed with both bio-resin and natural fibre reinforcements variants presented alongside more traditional carbon fibre parts.

Visitors will be able to get up close to a new Bio SUP Wingfoil board featuring a basalt, flax, bamboo and GreenPoxy bio-epoxy construction created for partners NSP, as well as state-of-the-art compression moulded prepreg foils. Cobra’s first fully recyclable surfboard incorporating the Recyclamine® resin technology that Cobra was recognised for in the 2020 JEC Innovation Awards will also be on display alongside a new Audi e-tron foil by Aerofoils – the world’s safest electric hydrofoil board.

The CAC team (Automotive Business Unit of Cobra) will present a set of OEM mirror cap parts that showcase a range of carbon SMC, woven visual carbon, pure woven visual flax, hybrid flax-carbon and painted flax construction options for the same component. Clear carbon aesthetic and structural parts including CAC made M-carbon components for the BMW S 1000 RR Motorcycle will furthermore underline the high quality and eye-for-detail for which CAC is renowned.

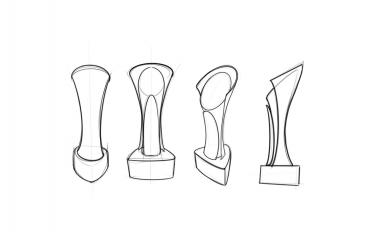

Carbon Prosthetics

An entirely new composite application for the company, Cobra will also show two composite prosthetic devices at JEC which were productionised by the in-house design and development team. Working alongside a leading Thai university and a medical device OEM, Cobra created a rapid and cost effective series production process for a lightweight carbon fibre prosthetic foot. In another example of lightweight composites creating major quality of life improvements, Cobra has also designed and manufactured a carbon and glass fibre prepreg foot support for Elysium Industries.

Cobra International