DiloGroup cooperates with Dell’Orco & Villani and TechnoPlants

With regard to current and imminent requirements to strengthen and promote the recycling of garment waste in order to safe valuable textile fibre in the European but also worldwide textile economy DiloGroup announces the start of a close cooperation between Dilo, Germany and the Italian companies Dell’Orco & Villani and TechnoPlants. This cooperation forms a group of expertise to supply complete projects in the area of textile recycling.

Dell’Orco & Villani is a long term highly experienced and innovative specialist in the field of tearing equipment to recycle textile garment clippings. This technology maintains as much as possible the staple length of reopened fibre from yarn in knitted and woven textiles. This special tearing process avoids the downgrading and shortening of the staple.

TechnoPlants is a highly experienced specialist in the field of aerodynamic web forming and through air technology with particular emphasis on reclaimed fibre for various applications as for example in acoustic and thermal insulation, car parts, upholstery and bedding.

DiloGroup with DiloSystems GmbH is a general contractor who is specialized in the area of fibre preparation, carding, cross-lapping and needling who will act as a turnkey general provider of complete projects including Dell’Orco & Villani components to reclaim wasted fibre as well as TechnoPlants components when aerodynamic web forming is included or when carding, cross-lapping is selected together with through-air ovens and end-of-line equipment including packaging from TechnoPlants.

The expertise of the three companies together is a source for the complete know-how in this large area of applications to reuse fibre from textile waste in new nonwoven material.

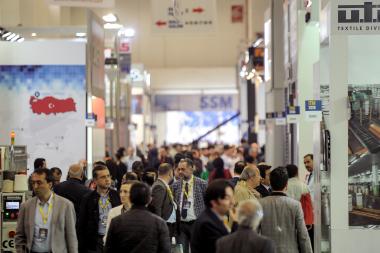

With the beginning of upcoming ITMA 23, more details of the organizational structure of this cooperation among the three companies will be released and project engineering will be started.

Oskar Dilo Maschinenfabrik KG