New Report by COBRA details Innovations in Windsurfing

Cobra International has launched an innovation report highlighting its key composite manufacturing innovations that have reshaped the Windsurfing industry.

Having first begun building windsurf boards in 1978, Cobra continues to drive technology development in the sport and 44 years later, manufactures approximately 80% of the world’s composite windsurf boards. Manufacturing for leading brands such as Fanatic, Starboard, Naish, RRD, JP and Quatro Goya, Cobra has consistently evolved and improved the construction and finishes of the boards that it builds, balancing stiffness, comfort, weight, strength, durability, and aesthetics.

Cobra’s report details key manufacturing innovations including:

- The introduction of its innovative vacuum moulding technique that Cobra perfected just as the popularity of the sport exploded.

- The manufacture of its own composite EPS forming moulds producing strong, watertight cores that are ready to use in production directly from the mould.

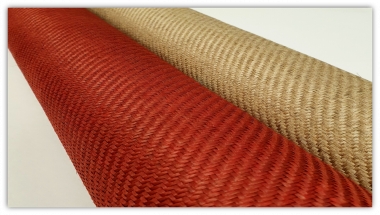

- The mass production of sandwich boards with thermoformed PVC foam wrapped around the rails, increasing the board’s strength whilst keeping weight to a minimum.

- Seamless rail construction

- High-volume manufacturing capacity optimized for the finest prepreg carbon foils satisfying the current demand for windsurf foiling equipment

- Development programs with on of the world’s leading carbon fibre fabric producers to create ever lighter biaxial fabrics.

“As we set aside time during the pandemic to upskill, innovate, and look to the future, it was also important that we referred back to our key technology successes. This got us thinking about so many of our developments which led us to create this innovation report. Customers can draw great confidence from the fact that the Cobra team is always working on tomorrow’s next generation product as well as building exceptional quality into each of today’s boards.” Bruce Wylie, CCO, Cobra International

COBRA International Co.,Ltd / 100 % Marketing