Modern Testing Methods for Raw Cotton

The 38th International Cotton Conference Bremen will take place from 25 to 27 March 2026 at the Bremen Parliament. The program will focus on technical innovations, market trends, and regulatory frameworks across the entire value chain – from agriculture to the circular economy. As well on the focus of high-profile speakers: Cotton quality and testing methods

Raw cotton from different areas of production varies considerably in terms of fibre properties, thus directly influencing how well cotton can be spun into yarn and how textiles behave in further processing. Innovative testing methods enable assessing each bale reliably and reproducibly according to defined quality parameters. The aim is to make cotton qualities comparable, as this is a key prerequisite for global trade, pricing and reliable supply chains. Quality and quality testing are the historical focus of the Bremen conference.

Real comparability on focus

Various methods for testing cotton include High Volume Instrument Testing (such as Uster HVI) as a common method for instrumental cotton classification for price deter-mination and bale composition; Uster AFIS for testing the length, fineness, neps, etc. of individual fibres and the Mesdan Contest as a thermomechanical method for deter-mining the tendency of cotton to stick together.

Mourad Krifa from Kent State University (USA) has been conducting research in the characterisation of cotton fibres for decades, focusing on length distribution. In his presentation he will introduce reliable statistical and software-based tools that help cotton growers, biotechnologists and processors to better analyse and utilise fibre distributions.

Dr Müge Ekizoğlu, İzmir Commodity Exchange (ICE), is going to present the certified storage and classification system for Turkish cotton based on instrumental classification using High Volume Instruments. As one of the leading cotton-growing and producing countries, objective quality assessment for export and international standards is crucial for the Türkiye.

Deninson Lima, ABRAPA Brazil, will present the results of a study on the measurement uncertainties determined for HVI devices used in Brazil. Based on the GUM standard, significant sources of uncertainty such as instrument design, environmental conditions, sample preparation and operator influence were analysed. The study quantified three repeatability, reproducibility and possible distortions and emphasises the importance of regular calibrations, quality controls and systematic uncertainty budgeting.

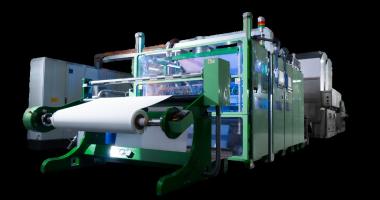

Gabriele Salvinelli, Mesdan, Italy, will present the Contest S series testing equipment. These super automated systems measure the stickiness of raw cotton, which can mess up spinning machines and may lead to higher maintenance effort as well as lower quality. Since standardised environmental conditions are often not fully complied with in practice, the study examines the extended humidity range in which reliable measurement results are possible and provides users with practical recommendations.

International Cotton Conference Bremen speakers Bremer Baumwolltagung Bremer Baumwollbörse

Bremer Baumwollbörse