Three ANDRITZ spunlace lines for Alar Silk Road New Materials in China

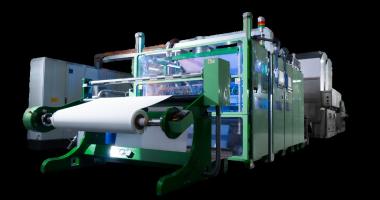

Alar Silk Road New Materials and ANDRITZ have successfully commissioned three spunlace lines in crosslapped configuration at Alar’s facility in Aral City, Xinjiang, China.

The new lines strengthen Alar’s capacity to produce high-quality nonwovens and support the development of a more resource-efficient and sustainable ecosystem for the region’s hygiene and medical industries.

The neXline spunlace lines from ANDRITZ process viscose and/or cotton fibers to produce nonwoven fabrics that meet stringent quality requirements for hygiene and medical end uses. The lines deliver excellent web uniformity, strong tensile properties, and high production rates, enabling Alar to meet the growing market demand. The latest Profile™ crosslappers help reduce operating costs by ensuring even fiber distribution.

ANDRITZ will continue to support Alar in further advancing its operations. The two companies plan to deepen their cooperation in innovation, digitalization, and energy efficiency to implement Alar’s goals and contribute to sustainable industrial development in the Xinjiang region.

Alar Silk Road New Materials Co., Ltd., based in Aral City, Xinjiang, is a leading producer of high quality nonwovens for hygiene, medical, and care applications. Using the region’s rich cotton resources, the company develops advanced materials supported by strong technological capabilities. Alar also drives innovation in renewable raw materials, converting resources such as reed into high value pulp, which supports circular economy goals. Through continuous collaboration and technological development, the company is building a modern, internationally competitive industrial base.

Alar Silk Road New Materials Andritz AG Andritz Nonwoven nonwovens medical textiles hygiene market

Andritz AG